Education & Resources

Explore our curated collection of Education & Resources, meticulously crafted to guide manufacturers on the path to excellence. From cutting-edge insights to foundational knowledge, each blog is a stepping stone towards elevating your production quality and operational efficiency. Dive in and unlock the potential of manufacturing mastery.

How to Implement Traceability in Manufacturing

In the rapidly evolving manufacturing industry, traceability has become a critical component for ensuring quality, compliance, and efficiency. Implementing a robust traceability system allows manufacturers to track the entire lifecycle of a product, from raw materials...

The Lean Manufacturing Approach to Cost Control

In today's highly competitive manufacturing landscape, controlling costs while maintaining high quality is paramount. Lean manufacturing, a methodology that emphasises efficiency by eliminating waste and optimising processes, offers a powerful approach to achieving...

Manufacturing Work Instructions: Best Practices for Quality

Clear and effective work instructions are crucial for ensuring quality and efficiency on the production floor. Work instructions provide detailed guidelines for workers to follow, helping to reduce errors, enhance safety, and maintain consistency in product output. As...

Why Your Factory Needs a Paperless Manufacturing System

In today’s manufacturing industry, efficiency, accuracy, and sustainability are more crucial than ever. The traditional paper-based methods are not only cumbersome and prone to errors but also environmentally unfriendly. Enter the paperless manufacturing system – a...

How to Create a Manufacturing Traveler

In the world of manufacturing, keeping track of production processes is crucial for efficiency, quality control, and traceability. A key tool for this purpose is the manufacturing traveler, a document that accompanies a product as it moves through different stages of...

Success with Manufacturing Traceability

In today's competitive manufacturing landscape, ensuring efficiency, product quality, and customer satisfaction is paramount. Traceability, the ability to track every step of the manufacturing process, plays a crucial role in achieving these goals. By implementing...

Simple Ways to Improve Sustainability in Manufacturing

Sustainability in manufacturing is no longer just a buzzword—it's a crucial element for the future of the industry. As environmental concerns grow and regulations tighten, manufacturers are seeking innovative ways to reduce their carbon footprint, minimize waste, and...

Solving Key Pain Points in Manufacturing with Tascus MES

One of the largest unseen impacts of the outdated manufacturing industry is the negative effect on people working in it. They are becoming demoralised, by building faulty products, caused by manual errors that could be avoided. The major inefficiencies holding back...

How to Measure and Increase Manufacturing Output

Increasing production output is a critical objective for any manufacturing business aiming to stay competitive. One of the most effective ways to achieve this is by accurately measuring and increasing manufacturing output. Understanding the key metrics and...

Essential Strategies for Increasing Production Efficiency

In the competitive world of manufacturing, production efficiency is crucial for maintaining profitability and staying ahead of the competition. Efficient production processes reduce waste, minimise costs, and ensure timely delivery of high-quality products....

Simple Ways to Cut Costs on the Manufacturing Floor

Manufacturing is a critical component of many businesses, but it also represents a significant portion of operational expenses. Streamlining processes and implementing cost-saving measures can have a substantial impact on the bottom line. Here are some effective...

Reducing Operational Risks on the Manufacturing Floor

Introduction In the fast-paced world of manufacturing, operational risks are a constant threat to efficiency, safety, and profitability. From equipment malfunctions to human error, these risks can lead to significant downtime, financial losses, and even injuries....

Exceeding Customer Expectations in B2B Manufacturing

Introduction In the competitive landscape of B2B manufacturing, exceeding customer expectations is crucial for fostering long-term relationships and driving sustained revenue growth. Unlike B2C transactions, B2B interactions involve complex, high-value orders and...

Enhancing Manufacturing Efficiency with Advanced Tech

In today's rapidly evolving industrial landscape, leveraging technology has become essential for maintaining a competitive edge. A recent study revealed that manufacturers implementing advanced technology solutions experience an average efficiency increase of 30%....

Cost-Effective Traceability Solutions for Manufacturers

Introduction In manufacturing, traceability means monitoring the journey of a product from the sourcing of raw materials, through the production process, and finally to the distribution and delivery to the end customer. This detailed tracking allows manufacturers to...

How Digital Tools are Enhancing Lean Manufacturing

A Recap on Lean Manufacturing Lean manufacturing is a systematic approach to production that aims to minimise waste while maximising value to the customer. Originating from the Toyota Production System, lean manufacturing focuses on creating more value with fewer...

Digital Transformation: Empowering Sustainable Manufacturing

Introduction Sustainability has become a critical operational imperative. Businesses face pressure to boost efficiency, reduce costs, and act in an environmentally responsible manner. Challenges include waste management, energy reduction, carbon footprint...

Data-Driven Manufacturing: Strategies for Success

In the ever-evolving landscape of manufacturing, striking the right balance between securing quick operational wins and laying the groundwork for long-term strategic goals is more critical than ever. This delicate balance is the key to not only surviving but thriving...

Improving Manufacturing Quality: 5 Simple Steps for 2024

Introduction In manufacturing, product quality is key to customer loyalty, reputation, and profitability. However, maintaining high quality is challenging due to variable raw materials, complex processes, and manual checks. These challenges are even greater when...

Automotive Digital Quality: The Future of Manufacturing

Embracing the Digital Age in Manufacturing In the dynamic landscape of the automotive industry, the relentless quest for manufacturing excellence is more than a journey—it's a constant evolution. As we step into the digital age, this evolution presents both a...

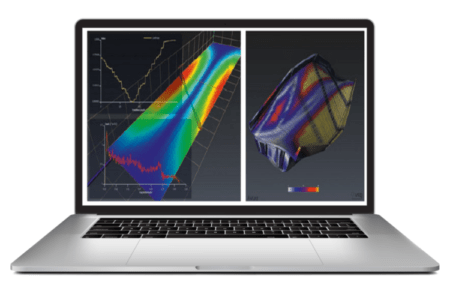

Revolutionising Manufacturing: The Power of Smart Analytics

Welcome to the Future of Manufacturing Picture a world where machines not only operate seamlessly but also have the foresight to alert you before they falter. Envision a manufacturing landscape where quality issues are identified and rectified well before they morph...

Achieving Zero-Defect Manufacturing with MES in Critical Industries

In industries where the stakes are exceptionally high, striving for zero-defect manufacturing is not merely ambitious—it's essential. This blog post explores the transformative role of Manufacturing Execution Systems (MES) in enhancing production outcomes. In...

The Analytics Revolution in Automotive Manufacturing: Navigating the Future with Data-Driven Precision

The automotive manufacturing industry, especially in areas like single-part production, is witnessing a transformative shift with the integration of data analytics into manufacturing processes. This evolution, propelled by Manufacturing Execution Systems (MES) and...

Striking a Balance in Manufacturing

Striking a Balance in Manufacturing: Immediate Results vs. Strategic Visions In the ever-competitive realm of manufacturing, industry leaders frequently face a significant challenge: striking a balance in manufacturing between achieving immediate results and pursuing...

Towards a Greener Future: Carbon-Neutral Manufacturing in Automotive

Introduction At the heart of the automotive industry's evolution lies a commitment to sustainability, with carbon-neutral manufacturing leading the charge. The shift from traditional, paper-based systems to cutting-edge digital processes is not merely a trend but a...

What is Total Quality Management?

Total Quality Management (TQM) is a management philosophy that focuses on continuous improvement in all aspects of an organization. It involves creating a culture of quality that permeates every level of the organization, from the top management to the shop floor...

How To Make Effective Digital Work Instructions

Leave Paper Behind and Revolutionise Your Assembly Processes Digital work instructions are an essential tool for the manufacturing industry, particularly for assembly operations. Digital work instructions replace traditional paper-based work instructions with digital...

Non Conformance Reports for Manufacturing

Hey, it's Martin from Metis Automation here. I’m going to talk about non conformance reports in the manufacturing processes. And the NCR or the non conformance report. More importantly, I am going to show you how Tascus can help and improve this process. The Current...

Measuring Manufacturing Downtime

Hi, Martin here from Metis Automation. In my video, I am going to talk about how to configure our Manufacturing Execution System – Tascus. You can use this fantastic tool to capture and record some of the downtime that you might experience in your manufacturing...

Tooling Traceability for Manufacturing Processes

Tool Traceability When manual tools are used in the manufacturing process, it is very important for quality standards to record exactly which tool reference number has been used. It is also important to keep that aligned with its calibration records and its service...

Visual Work Instructions for Manufacturing Processes

Visual work instructions for a manufacturing process. What are they and why are they useful? Firstly, having things explained in a clear visual way, can speed up the training process, reduce errors and help to standardise processes across a manufacturing company....

Creating Digital Manufacturing Travellers

Digital manufacturing travellers in a manufacturing process are required for traceability purposes. It's where you record every stage and every operation in the manufacturing process that's been completed. You capture key information like quality inspections,...

How to Get Started with a Manufacturing Execution System

How would you get started with implementing a Manufacturing Execution System? There’s quite a lot already happening in manufacturing, and the process itself is complicated enough as it is. But what really affects the bottom line, is how you manage these processes. A...

Streamlining Manufacturing Travellers

Are your manufacturing travellers optimised for efficiency? While they're crucial for tracking processes and ensuring quality, unnecessary duplicate entries can lead to confusion and wasted time. Streamlining your manufacturing travellers is essential to eliminate...

How to do Manufacturing Capacity Planning

Every successful business has its own methods of achieving. More likely than not, if you have a successful business, you probably have high demand and make excellent profit from it. However, you can have as many clients lined up as you wish, but are you in control of...

Reducing Variation in your Manufacturing Process

Control is an imperative part of any manufacturing process, and reducing variation is a big step in ensuring control. Why? Because variation is a clear indicator that your manufacturing process is out of control. A high-quality process means the difference between...

How to Improve Visual Product Inspection

Visual product inspection is critical, but we’re all only human – and humans are prone to error. While your factory likely has plenty of verification testing and automated inspections in place, it’s not uncommon for problems to continue slipping through the cracks. In...

How to Reduce Machine Downtime

Machine downtime can have a big influence on everything in your manufacturing process. In fact, not only does it affect the manufacturing process, but it can take a toll on your business operations as a whole. If you’ve experienced losses due to machine downtime,...

Ways You Can Improve Your Machine Productivity

There’s little worse than having a slow production process. You can easily talk to unproductive employees, but slow machines are a different story altogether. Do you know what you call a process that has one thing slowing it down? A bottleneck. In order to run a...

Improving Production Visibility for Successful Processes

What does it mean to have good visibility of your production processes? Well, simply put, you need to know exactly what’s going on in your production process in order to make the right decisions when it comes down to the crunch. When companies don’t have sufficient...

Defeating the Predictable: How to Detect and Prevent Manufacturing Mistakes

Preventable mistakes in the manufacturing process are frustrating and annoying for your customer. But, they are also low hanging fruit for business improvement. When you have identified several mistakes that keep occurring in your manufacturing process or you have...

How Can You Get Your Manufacturing Operations Team Working Remotely?

You rely on your manufacturing operations team to expedite production orders, to ensure that targets are met and orders fulfilled. With paper-based production systems, it’s impossible for operations teams to manage work in progress, from home. A Manufacturing...

How Can Manufacturers Work Remotely?

Remote working has been popular with software companies and freelancers for the past 10 years, but it hasn't really taken off yet with manufacturers. With the current global pandemic of coronavirus, most government advice is to remote work where possible. So, in this...

What is the ROI for a Manufacturing Execution System?

Manufacturers are now using digital manufacturing software to integrate Industry 4.0 technology in their operations. This enables them to go paperless on their shop floor and to improve their manufacturing processes. However, a Manufacturing Execution System (MES) can...

The Ultimate Guide to Manufacturing Execution Systems in 2023

How Does a Manufacturing Execution System Work? A MES helps guide production operators step by step, through all the tasks required to transform raw materials into finished goods. It does this using digital work instructions, production routings and connecting to...

7 Ways to Grow With an MES

Investing in new production processes is a major step for any business. It requires balancing of the costs in time and money versus the benefits the business will reap in the future. Using an MES helps you succeed by focusing on what your customer wants at every point...

Improve Profits Through Accurate Labour Costs

To improve profits, manufacturers need to keep tight control of material and labour costs. When jobs are estimated and quoted to customers, they are based on standard labour times for each manufacturing process. But when products are moving through your factory, how...

5 Ways to Increase Manufacturing Productivity with an MES

In order to remain competitive, manufacturers need to maintain high manufacturing productivity – or high revenue generated per employee. Most methods of improving manufacturing productivity begin with a thorough analysis of a company’s systems and manufacturing...

Digitalising Manufacturing

I visited the Manufacturing Technology Centre in Coventry for a Digitalising Manufacturing Conference, where I had the chance to discuss the benefits that digital manufacturing can bring to manufacturing businesses, and also some of the roadblocks to its full adoption...

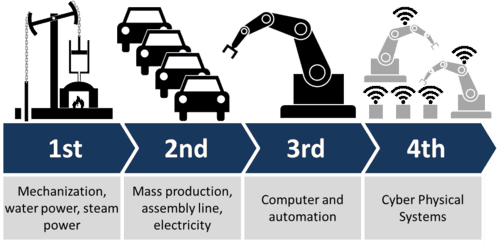

Industry 4.0 Guide – An Overview

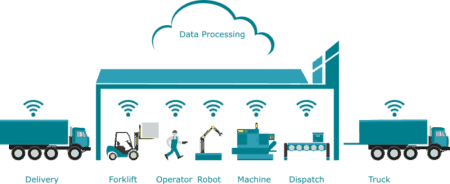

We are currently experiencing the 4th Industrial Revolution, where machines and manual operations are being connected together to bring the benefits of automation to entire production processes and factories. The term Industry 4.0 was coined in Germany, as a proposed...

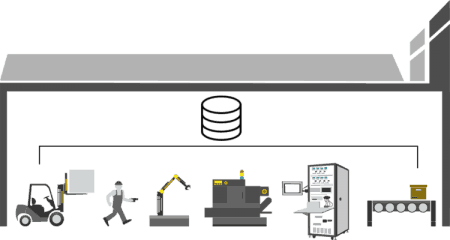

Industry 4.0 Guide Part 1 – Creating a Secured Network Factory

The benefits of Industry 4.0 are achieved when computers can collate production data and make production decisions that are currently made manually. The first step to implementing this is connecting each production operation and machine with a secure network...

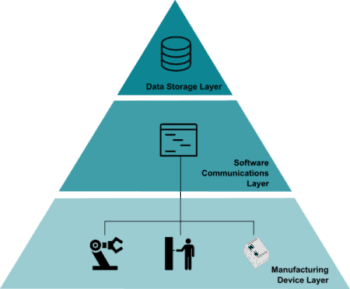

Industry 4.0 Guide Part 2 – Connecting Devices Throughout Your Factory

Device Communications Once a secure network that enables a connection between production devices is in place, a system must be created for connecting devices that will allow production machines to communicate with each other. There are two main reasons for enabling...

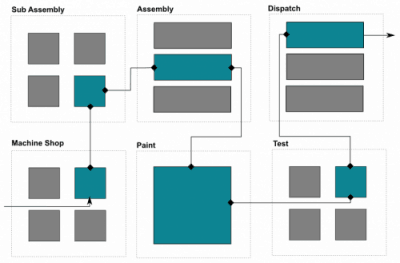

Industry 4.0 Guide Part 3 – Connecting Production Operations

Connecting production operations is the first step in creating a paperless factory. This can deliver large increases in production efficiency and reduce the lead time of manufacturing products. Many production systems control product routings manually. A bill of...

Industry 4.0 Guide Part 4 – Improving Your Business With Production Data Analytics

Once manufacturing operations are connected to IT systems, large amounts of production data can be gathered. However, it then needs to be converted from large volumes of unsorted production data, into data that is relevant to business processes. By performing...

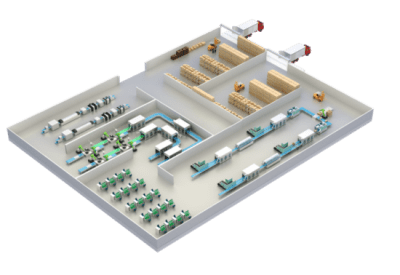

Paperless Manufacturing

Paperless Manufacturing is when work orders and work instructions needed to control the production process, are replaced by an IT System that connects to manufacturing processes. The IT System then controls and guides the production process, resulting in increased...

Mass Customisation

Mass Customisation is when a manufacturer creates completely customised products at the same scale and cost of mass-produced items. Key Features of Mass Customisation: Customers and suppliers collaborate to create customised products. Unique product designs are...

Industry 4.0

Industry 4.0 (otherwise known as connected manufacturing)was developed in Germany as a proposed way for SME manufacturers to remain competitive and relevant in the future. German business leaders recognised that their factories could not compete with low-cost...

Connected Manufacturing

Connected Manufacturing is a factory automation system where manual and automated manufacturing processes are connected together. As a result, this allows the automation of entire manufacturing processes and production planning. Key features of Connected...

Smart Tools in Manufacturing

Smart Tools are a low-cost investment that can transform manufacturing processes and save costly rework or product recalls. This article will outline their basic operation and the strategies for using them in assembly and manufacturing operations. What Are Smart...

Transformation of the Automotive Industry

The current state of the UK automotive industry is extremely healthy, with vehicle manufacturing at its highest level since 2005. Vehicles built in the UK now have 15% more UK content than they did in 2012. However, there are dramatic changes happening in the...

Fully Connected Factories Predicted by 2022

Zebra Technologies’ recently published "2017 Manufacturing Vision" predicting that by 2022, the majority of manufacturers will have fully connected factories. It has also identified that manufacturers are currently connecting operations to gain greater visibility and...

LabVIEW Developer Days Manchester – Day 2

Local LabVIEW Developers gathered together in June for National Instruments LabVIEW Developer Days Manchester. The NI team of Jason, Peter, and Charlotte, accompanied by Metis Automation's Technical Director Martin Griffiths, hosted a collection of sessions aimed at...

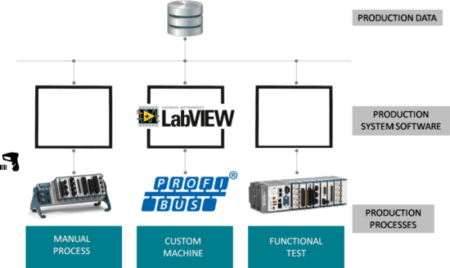

Connected Manufacturing & Production Test Systems

How does Connected Manufacturing affect production test systems in factories ensuring that high-quality products are shipped to customers? Explore how Connected Manufacturing is being implemented in businesses, and how test systems need to adapt to be ready to...

Key Lessons Learnt from Implementing Connected Manufacturing

In the last couple of months, I’ve attended two events focused on manufacturers implementing Connected Manufacturing and Industry 4.0. It’s great to get out there and learn about the successes and challenges other companies are experiencing. Key Lessons Learned...

Connecting Customers with Connected Manufacturing

Connected Manufacturing Systems In a recent project, a client of ours who we have been developing Connected Manufacturing systems for over 2 years, asked us to help them send production data directly to their customer. The aim of this was to improve the way our...

NI Days 2016 Review – Software Development

At the User Group track during this year’s NI Days, engineers and scientists heard from talented LabVIEW software developers discussing the lessons they had learnt from many years of projects implementing solutions with high quality LabVIEW software. James...

The Dawn of a New Manufacturing Frontier

Martin discusses the evolution of manufacturing processes and the dawn of the next stage – Mass Customisation, in an article published in Control Engineering Europe magazine. Mass Customisation is the ability to create custom, almost bespoke products at the same...