Solving Key Pain Points in Manufacturing with Tascus MES

One of the largest unseen impacts of the outdated manufacturing industry is the negative effect on people working in it. They are becoming demoralised, by building faulty products, caused by manual errors that could be avoided.

The major inefficiencies holding back the manufacturing industry, have caused it to have an outdated image, leading to less young people choosing manufacturing as a career path.

For every Toyota or Airbus with a robot-driven, fully automated factory, there are a thousand more manufacturers, still reliant on unreliable paper processes. Leading to hundreds of wasted hours per month, on unnecessary admin work.

We’ve been working with manufacturers for over 12 years now, and we’ve found 4 key pain points to be resolved:

Revitalise Your

Manufacturing Environment

Download our free Digital Transformation Starter Kit. Equip your team with the right tools and knowledge to minimise operational risks and improve safety.

In this article:

Ensuring Superior Product Quality with MES

With product quality issues, a company risks losing customers, or losing new business, if a competitor has an MES, to ensure product quality, and they don’t. One international aerospace company lost an order worth over £35M, for this very reason.

Lay the Groundwork for Quality Assurance

Start addressing quality control with our Starter Kit, preventing avoidable errors and setting up for Tascus’s advanced solutions

Enhancing Traceability for Compliance

and Efficiency

Being able to trace how products have been manufactured, is essential for compliance purposes. For growing manufactures, recording this on paper, has become an impossible task. We are working with several automotive companies who in the past have received hundreds of thousands of pounds in penalty charges from OEMs.

Boosting Productivity Through Automation

and Innovation

Manufacturing companies compete in a global market, and are under constant pressure from customers, to lower their costs and pass on those cost savings. It’s a necessity to have high productivity, to maintain healthy profit margins. With our system, clients have reduced operator training time, from 6 months, down to 2 weeks.

Initiate Productivity Gains

Leverage our Starter Kit to enhance operational efficiency and sharpen your competitive edge without overextending resources.

Achieving Real-Time Data Visibility for Optimal Decision Making

To fix problems and ship product on time, is necessary, to run a productive factory. One Biotech company employs 6 full-time managers, just to manually track production. If they weren’t doing this manually, they could better spend this time on value adding tasks.

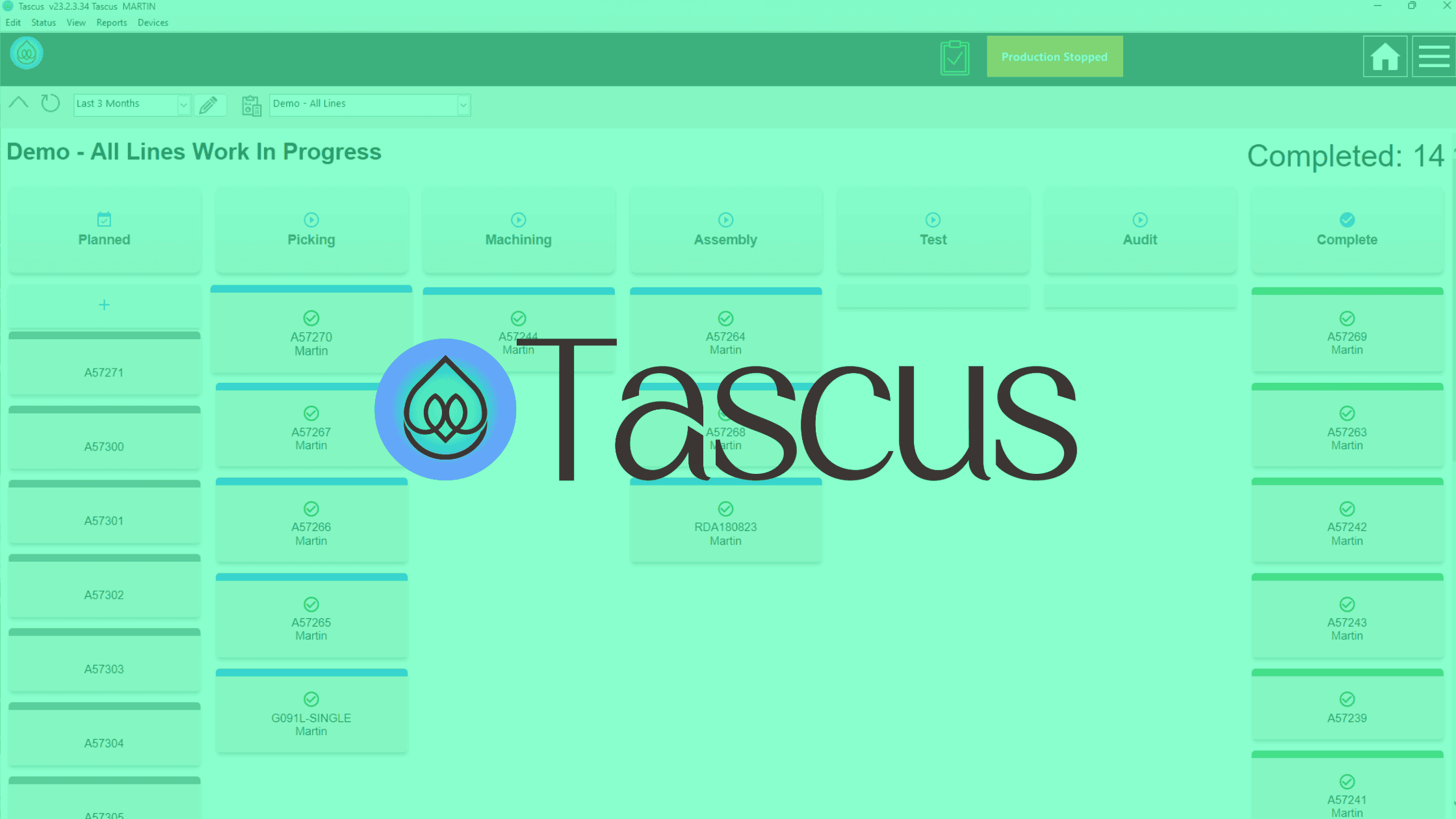

Implementing Tascus MES for Manufacturing Excellence

Our solution is Tascus, a digital Manufacturing Execution System, (MES), that frees those who work in manufacturing, from unnecessary data collection and ensures that products are built right-first time.

It automatically traces every step of the manufacturing process,

whilst monitoring productivity, and provides real time visibility across the business.

Tascus also automatically collects 1000’s of data points, that can be used to track business, Key Performance Indicators, and quickly diagnose problems, in the manufacturing process.

By leaving these issues unresolved, manufacturing companies, who are still reliant on paper and spreadsheets are slipping further behind their competitors. They struggle to win new business when their quality performance drops and their costs inevitably rise.

Prepare for Tascus with

Our Starter Kit

Set the foundation for advanced manufacturing with tools from our Starter Kit, paving the way for full Tascus integration.

Tascus has enabled our clients to win new business, worth £ Millions annually, with a clients they wouldn’t have been able, to bring on board, without the use of our software.

Tascus has had 1000’s of hours of use in factories, by our clients in automotive, pharmaceutical, and electronics.

They tell us that they couldn’t have grown their businesses to where they are now, without the use of Tascus.

They would need an army of admin staff, to manage the paperwork that increased production volume brings.

They would be less competitive, and they wouldn’t have won and kept their loyal clients.

We envision a manufacturing industry, that’s automated, efficient, and attractive for young people to join, for decades, to come.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?