The Simple Way to

Improve Quality & Production

Tascus helps manufacturers reduce errors,

speed up production, and stay compliant – without the

hassle of paperwork or complex systems.

Quality

Traceability

Productivity

Visibility

Tascus takes the guesswork out of manufacturing by guiding operators, automating quality control, and giving manufacturers complete visibility over production.

Fewer Mistakes – Operators follow clear, on-screen instructions.

Faster Workflows – No delays, no hold-ups, just a smooth process.

No More Paperwork – Everything is tracked automatically.

Screenshot Award Winning MES – Tascus.

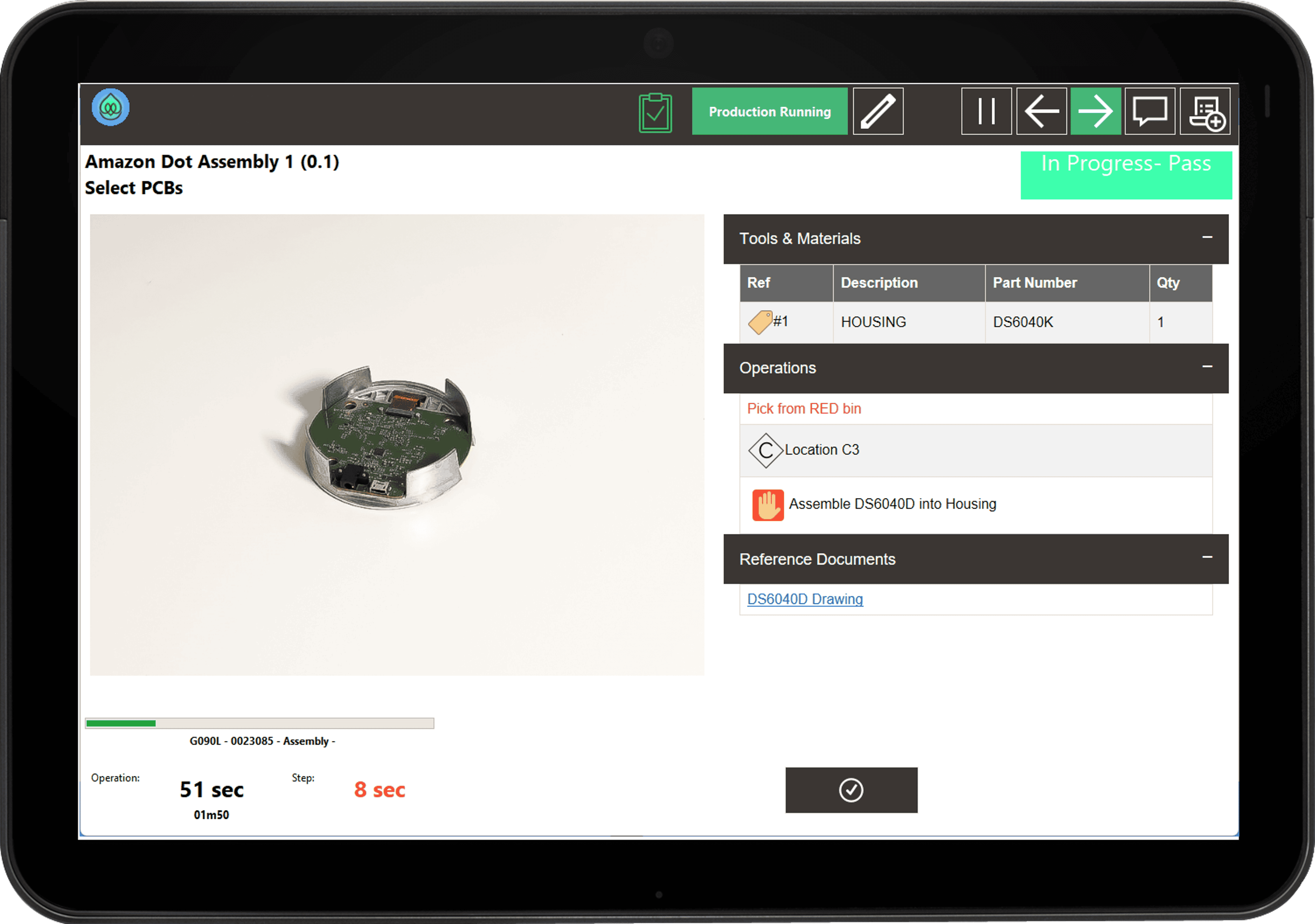

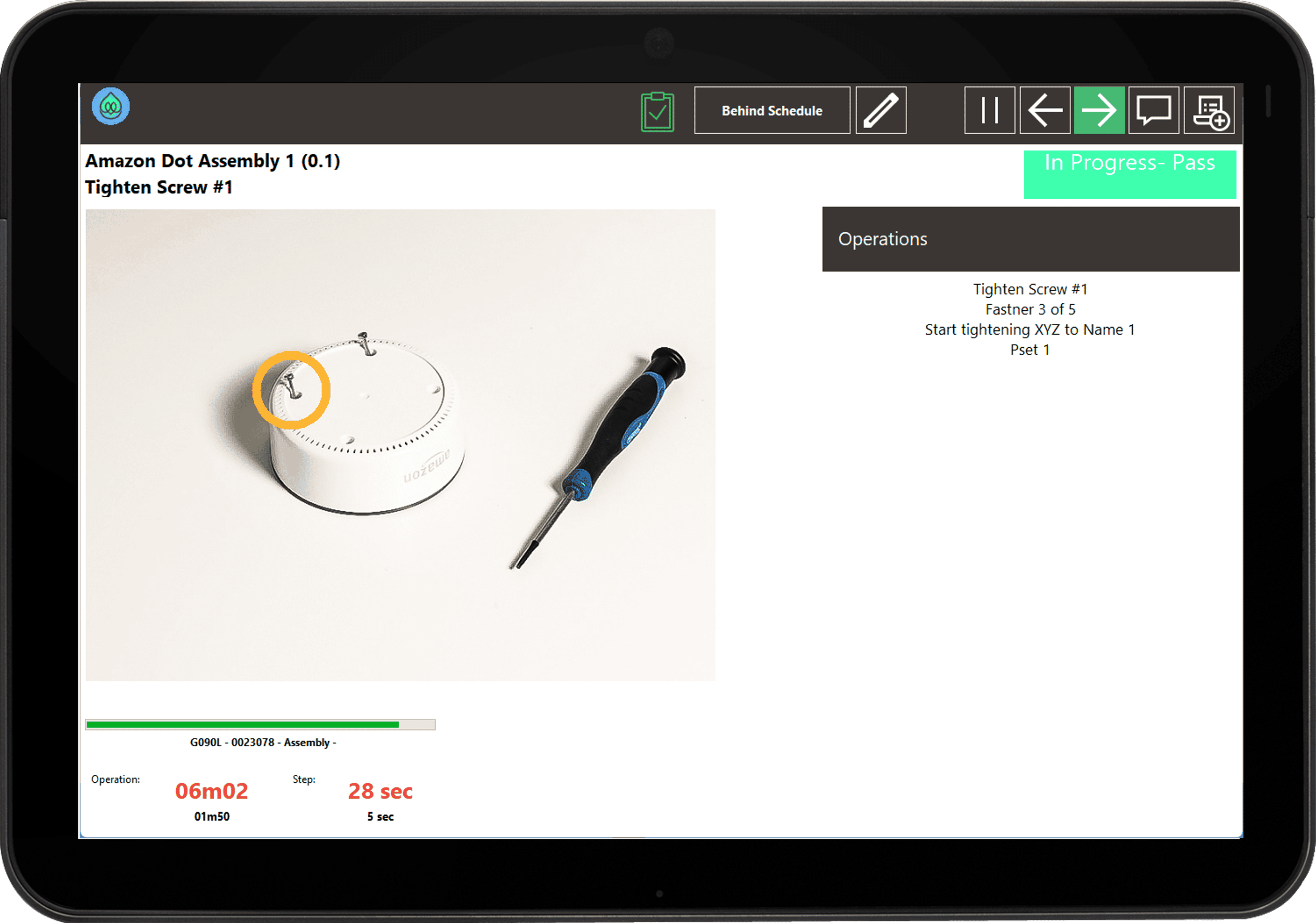

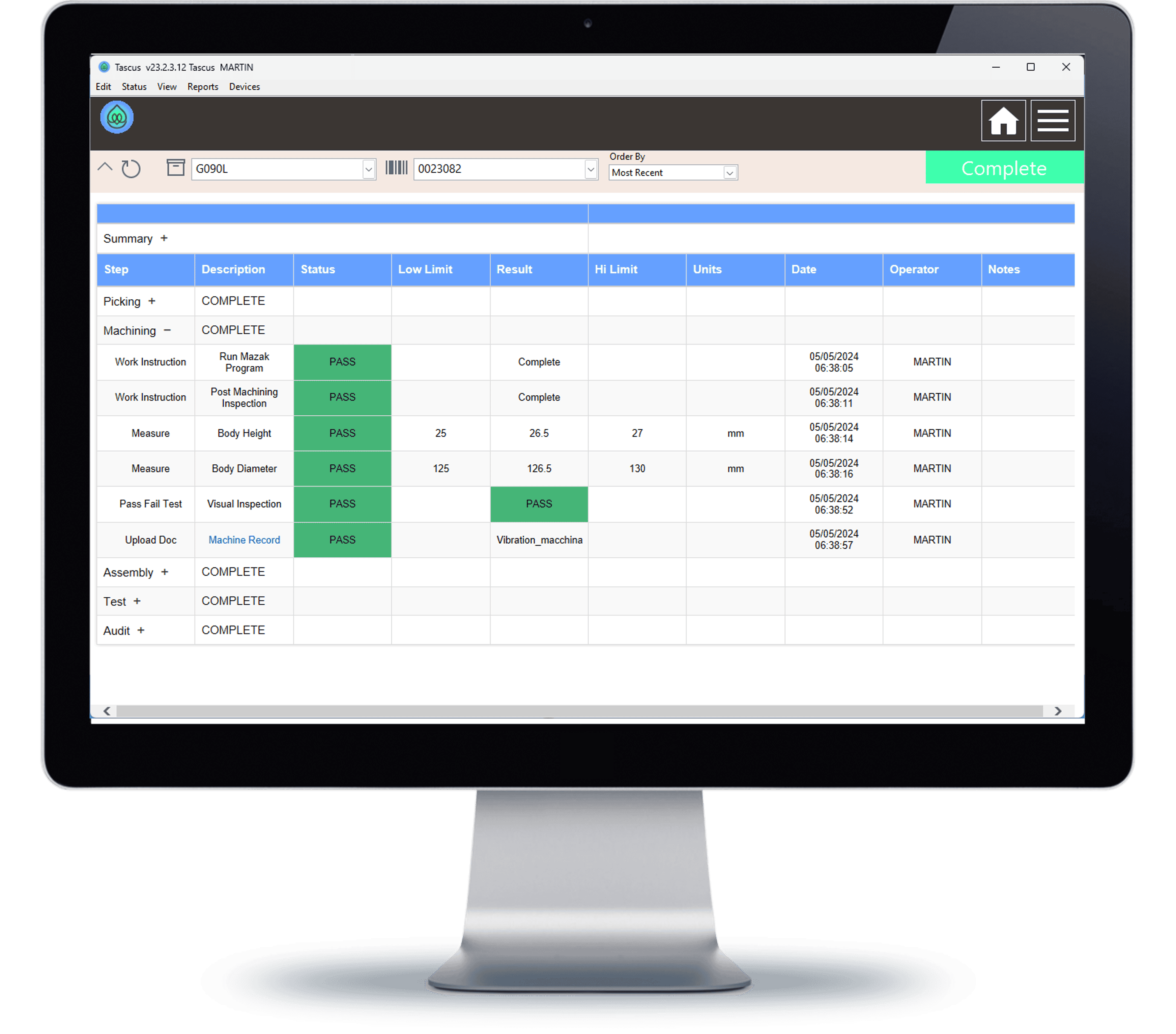

Product Build Instructions

Clear, step-by-step digital instructions to ensure every build is done right the first time. Reduce errors, speed up training, and keep production consistent.

- No more paper manuals – keep operators on track with clear, digital instructions.

- Reduce mistakes and waste by ensuring every build follows the correct steps.

- Instant updates – push new instructions factory-wide in seconds.

- Train new staff faster with step-by-step visual guidance.

- Full traceability – every step is logged for full visibility of who did what, and when.

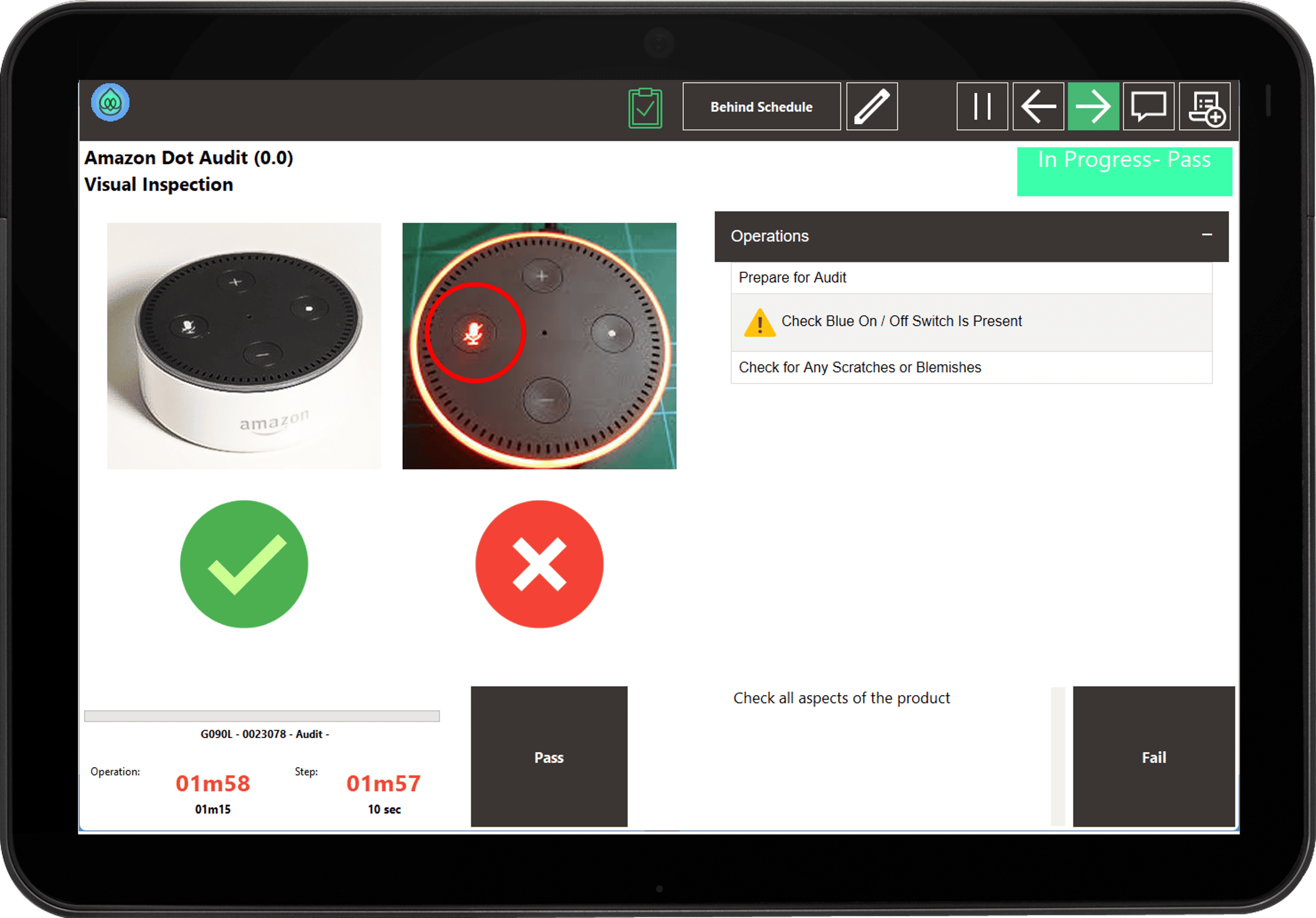

Built-in Quality Checks

Prevent defects before they cause delays or waste. Tascus catches mistakes in real time, so issues are fixed fast, and production stays on track.

- Add quality checks at critical points to catch issues immediately.

- Stop defects from moving forward by ensuring each step is completed correctly.

- Provide operators with clear, on-screen prompts for consistency.

- Reduce scrap and rework by addressing errors at the source.

Screenshot Award Winning MES – Tascus.

Screenshot Award Winning MES – Tascus.

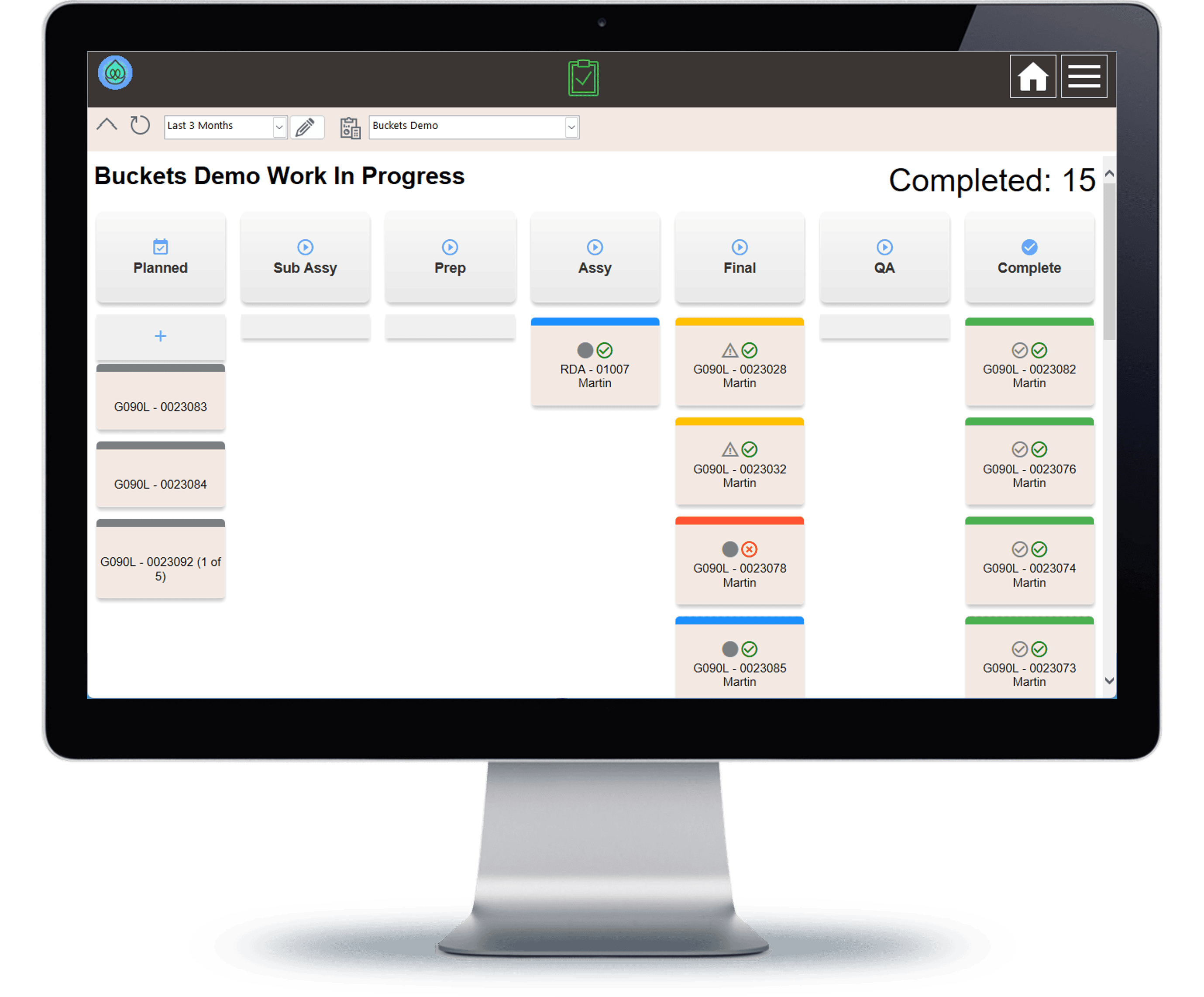

Live Production Tracking

- Check job progress instantly – no more chasing updates.

- Spot delays early and fix issues before they disrupt production.

- Automatically log key data like batch numbers and inspections.

- Eliminate manual data entry for accurate, real-time records.

Full Production Overview

- See work-in-progress instantly – track every job as it moves.

- Identify bottlenecks early – fix slowdowns before they impact production.

- Get live status updates – always know what’s running on time and what’s not.

- Make fast, informed decisions based on real-time factory insights.

Screenshot Award Winning MES – Tascus.

Screenshot Award Winning MES – Tascus.

Paperless Production Records

Go paperless and track every job digitally. Tascus records every step automatically for full traceability and compliance.

- Every step is recorded automatically – from manual inputs to machine data.

- Instantly find job history – no more searching through paperwork.

- Meet regulatory requirements effortlessly with built-in traceability.

- Ensure accuracy and accountability – no extra admin work needed.

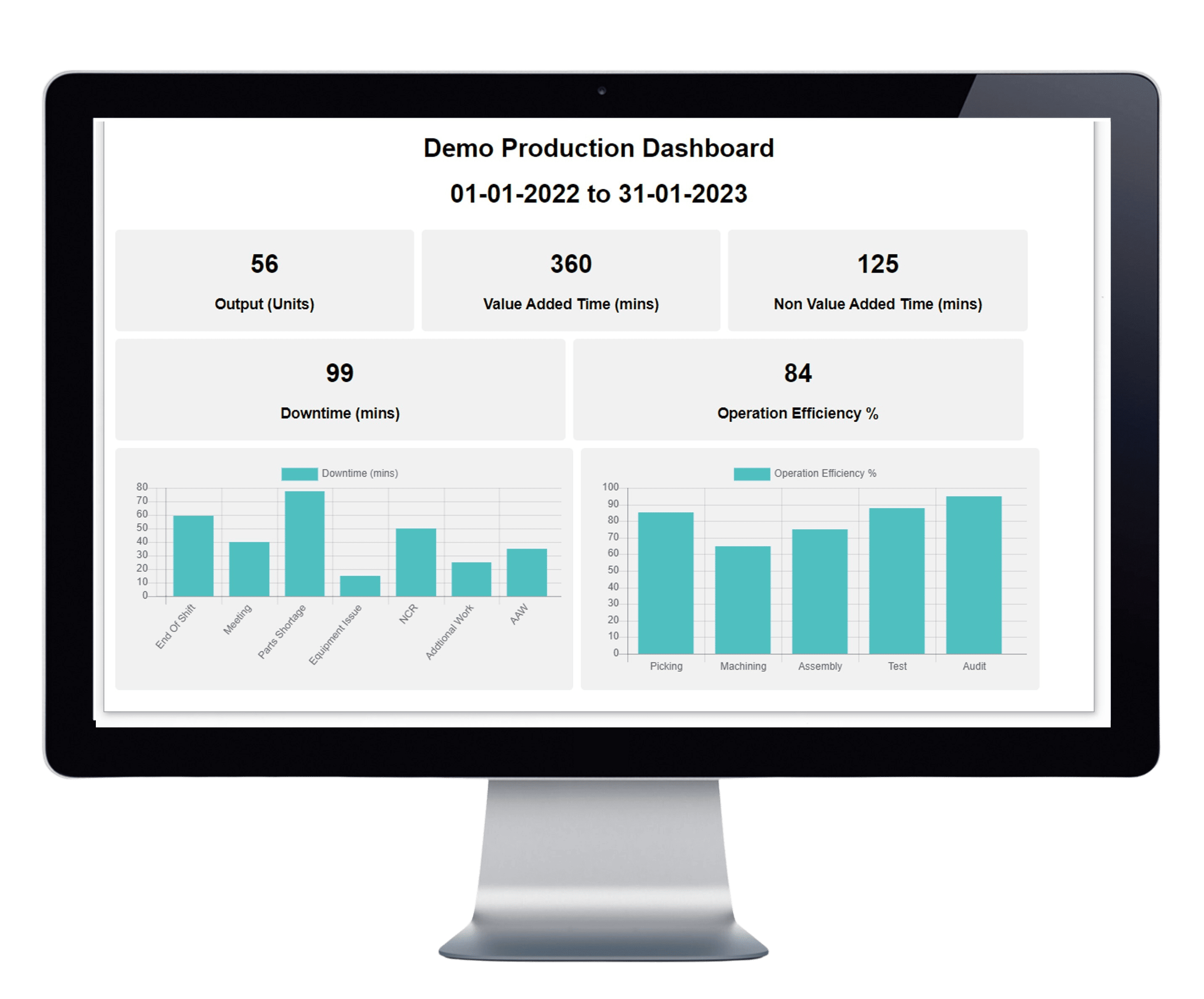

Production KPI Tracking

See the numbers that matter. Tascus gives you real-time dashboards to track performance and improve efficiency.

- Monitor live production data and catch inefficiencies early.

- Customise dashboards to focus on what matters most to your business.

- Automate reporting to reduce time spent on spreadsheets.

- Make faster, data-driven decisions with real-time insights.

Screenshot Award Winning MES – Tascus.

Tascus FAQs:

Does Tascus track operator performance?

Yes, Tascus logs every task completed, tracking who did what and how long it took. This helps monitor efficiency, reduce bottlenecks, and improve accountability.

Can Tascus manage rework and corrective actions?

Tascus tracks and manages rework tasks, ensuring defects are resolved quickly. Operators receive clear corrective instructions, and all actions are logged for full traceability.

Does Tascus support equipment maintenance?

Yes, Tascus provides step-by-step maintenance checklists to ensure machines are inspected before production begins. This helps reduce downtime and prevent failures.

Can Tascus integrate with our existing systems?

Yes, Tascus connects with ERP & MRP systems, allowing for automated work orders, real-time production updates, and seamless data synchronisation.

How does Tascus improve factory-wide control?

By integrating with IoT-enabled machines, barcode scanners, RFID, and smart tools, Tascus provides real-time production monitoring so you can track jobs, materials, and performance effortlessly.

%

Right First Time

%

Training Reduced (6 months-2 weeks)

%

Rework Reduced by

Resources to Get Started

💡 New to Digital Work Instructions?

Learn how digital work instructions improve accuracy and efficiency.

🛠 How to Transition from Paper-Based Processes

Follow our 4-step process to go paperless and streamline operations.

📈 See How Tascus is Helping Manufacturers Like You

Read case studies on real-world success with Tascus.

🔧 The Essential Manufacturing Shutdown Checklist

Plan a smooth shutdown and restart

📊 What is an MES?

Understand how MES can improve your factory