Simple Ways to Improve Sustainability in Manufacturing

Simple Ways to Improve Sustainability in Manufacturing

Sustainability in manufacturing is no longer just a buzzword—it’s a crucial element for the future of the industry.

As environmental concerns grow and regulations tighten, manufacturers are seeking innovative ways to reduce their carbon footprint, minimize waste, and enhance overall efficiency. By adopting sustainable practices, companies not only contribute to a healthier planet but also enjoy long-term economic benefits.

Here are three simple yet effective ways to improve sustainability in manufacturing:

Embracing Sustainability

in Manufacturing

Start greening your operations with our Digital Transformation Starter Kit.

In this article:

Optimise Energy Usage

Energy Audits and Monitoring: Conduct regular energy audits to identify areas of high consumption and potential savings. Implementing energy-efficient lighting, heating, and cooling systems can significantly reduce energy usage.

Renewable Energy Sources: Invest in renewable energy sources such as solar or wind power. This not only reduces dependency on fossil fuels but also cuts down on greenhouse gas emissions.

Maximise

Energy Efficiency

Energise your setup with our Starter Kit

for smarter energy use.

Reduce Waste Through

Lean Manufacturing

Lean Principles: Adopt lean manufacturing principles to streamline production processes, reduce waste, and improve efficiency. Techniques such as Just-in-Time (JIT) production ensure materials are used only when needed, minimising excess.

Recycling and Reusing Materials: Implement recycling programs for scrap materials and encourage the reuse of by-products. This can lead to significant cost savings and environmental benefits.

Implement a Digital Manufacturing

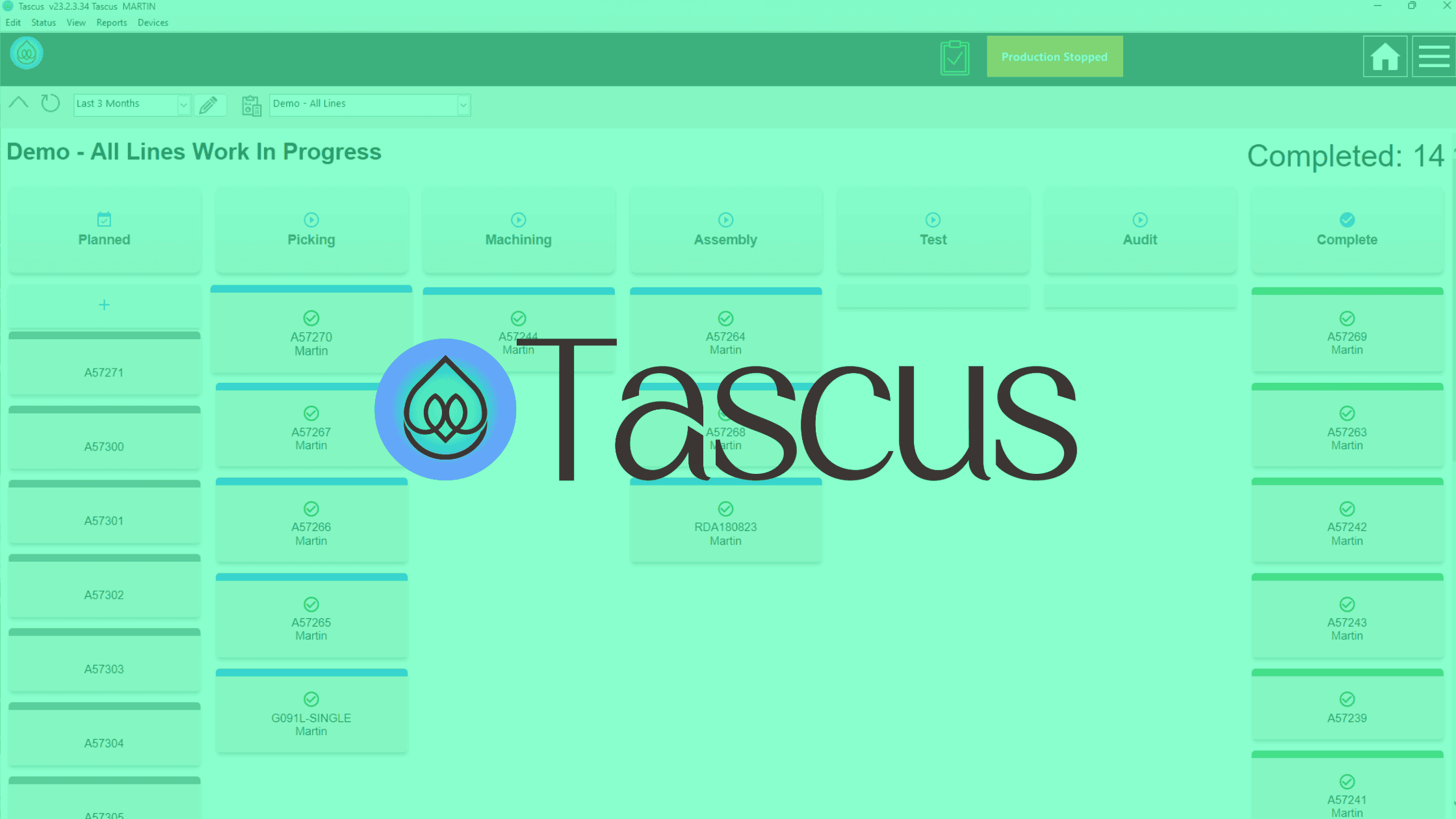

Enhanced Process Control: A Manufacturing Execution System (MES) like Tascus from Metis Automation can provide real-time monitoring and control of production processes. This leads to optimised resource use, reduced waste, and improved quality control.

Data-Driven Decision Making: MES systems collect and analyse data across the manufacturing process, identifying inefficiencies and areas for improvement. By leveraging this data, manufacturers can make informed decisions that enhance sustainability.

Lean Toward Sustainability

Streamline processes and reduce waste with our Starter Kit.

Final Thoughts

Improving sustainability in manufacturing is a journey that requires commitment and continuous improvement. By optimising energy usage, reducing waste through lean manufacturing, and implementing advanced systems like MES, manufacturers can make significant strides toward a more sustainable future.

Embracing these practices not only benefits the environment but also drives efficiency, reduces costs, and enhances the overall competitiveness of the business.

We Help Manufacturers

Make Great Quality Products

Let's talk! Book a 1:1 call with our

CTO to discuss your digital transformation.