Exceeding Customer Expectations in B2B Manufacturing

Exceeding Customer Expectations in B2B Manufacturing

Introduction

In the competitive landscape of B2B manufacturing, exceeding customer expectations is crucial for fostering long-term relationships and driving sustained revenue growth.

Unlike B2C transactions, B2B interactions involve complex, high-value orders and long-term contracts. Ensuring customer satisfaction in this context requires a strategic approach that focuses on personalised service, quality assurance, and continuous improvement.

This article explores how B2B manufacturers can exceed customer expectations to achieve higher client retention and increased revenue.

Optimise Your Manufacturing Process

Our Digital Transformation Starter Kit helps you move from paper to digital with practical templates and guides.

Strategies for Exceeding Customer Expectations

1. Customised Solutions

Tailored Manufacturing Processes: Develop flexible production processes that can be easily adjusted to meet specific client requirements – read more. This customisation demonstrates a commitment to addressing unique business needs and enhances client satisfaction.

Personalised Service Offerings: Provide clients with options to customise products and services, ensuring that the solutions provided align closely with their operational goals and market demands.

Collaborative Product Development: Engage clients in the product development process, seeking their input and feedback to create solutions that precisely meet their needs. This collaborative approach fosters a sense of partnership and investment in the final product.

Revitalise Your

Manufacturing Environment

Download our free Digital Transformation Starter Kit. Equip your team with the right tools and knowledge to minimise operational risks and improve safety.

Strategies for Exceeding Customer Expectations

2. Proactive Communication and Support

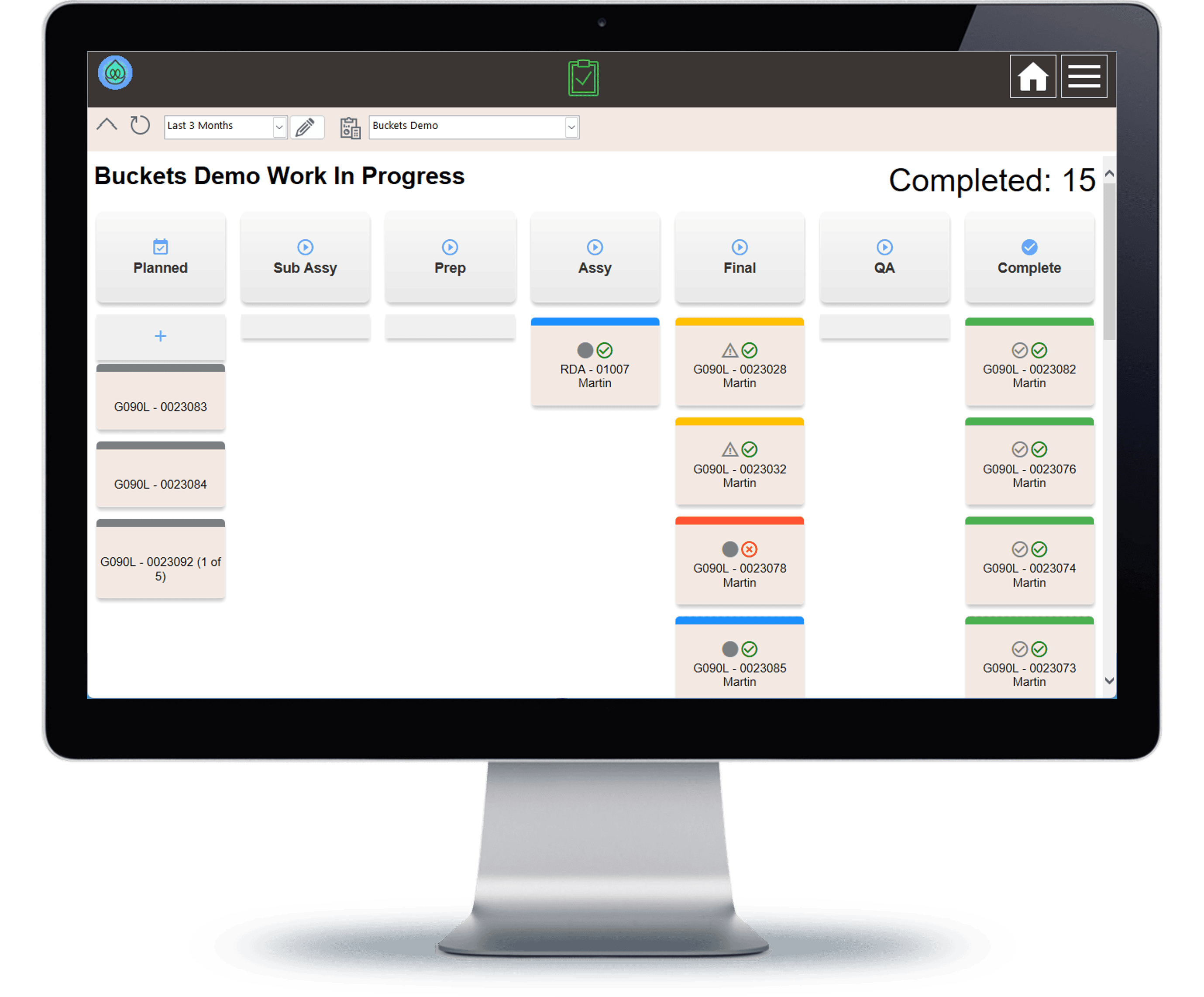

Regular Updates and Transparency: Maintain open and frequent communication with clients regarding project status, potential challenges, and delivery timelines – read more. Transparency builds trust and keeps clients informed, reducing uncertainty and enhancing satisfaction.

Dedicated Account Management: Assign dedicated account managers who understand each client’s business intimately. This personalised attention ensures that clients feel valued and their concerns are promptly addressed.

Robust After-Sales Support: Offer comprehensive after-sales support, including technical assistance, maintenance services, and training. Ensuring that clients can efficiently use and maintain the products provided enhances their overall experience and satisfaction.

Strategies for Exceeding Customer Expectations

3. Commitment to Quality and Innovation

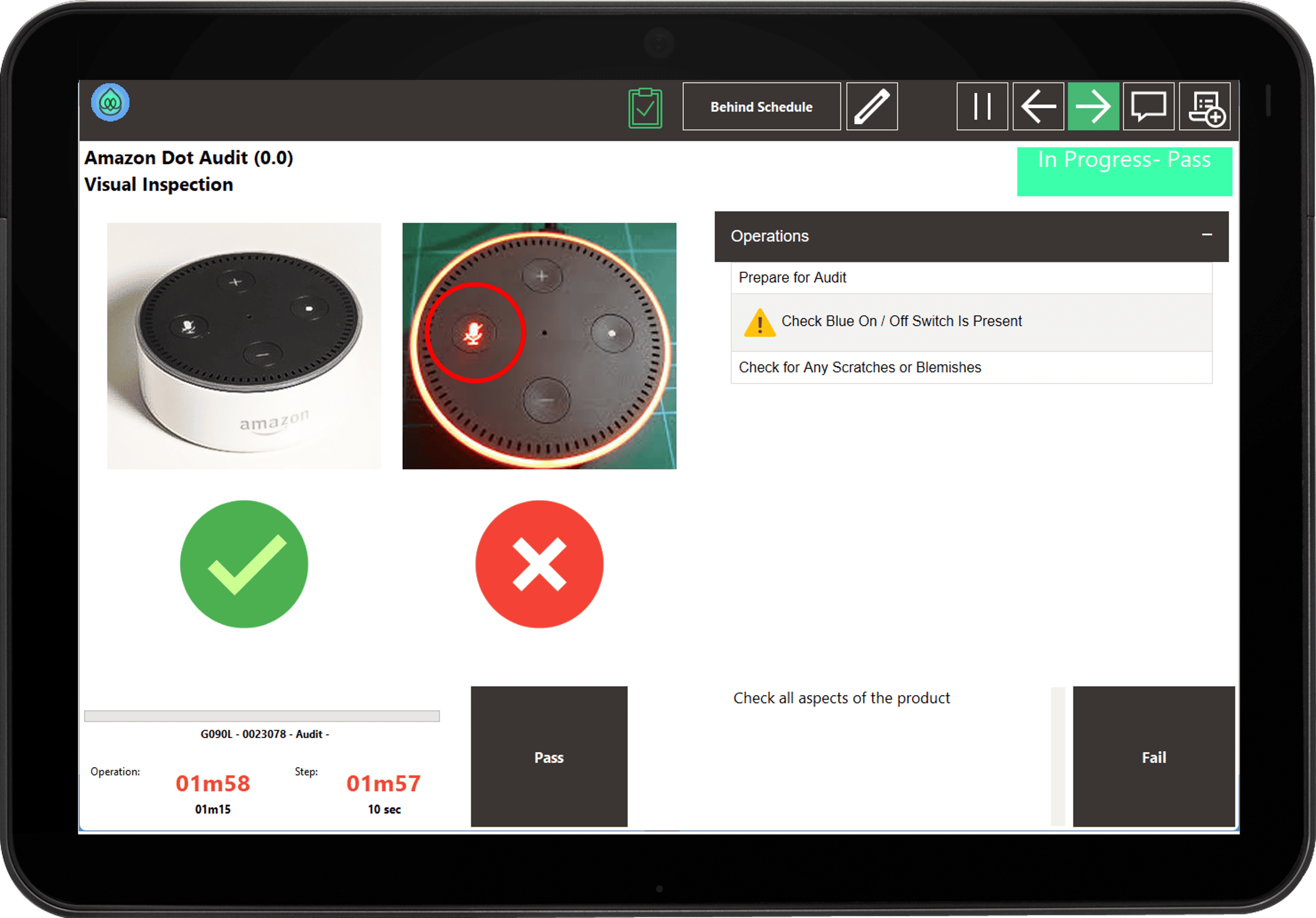

Stringent Quality Control: Implement rigorous quality control measures to ensure that all products meet or exceed industry standards – read more. Consistently delivering high-quality products builds a reputation for reliability and excellence.

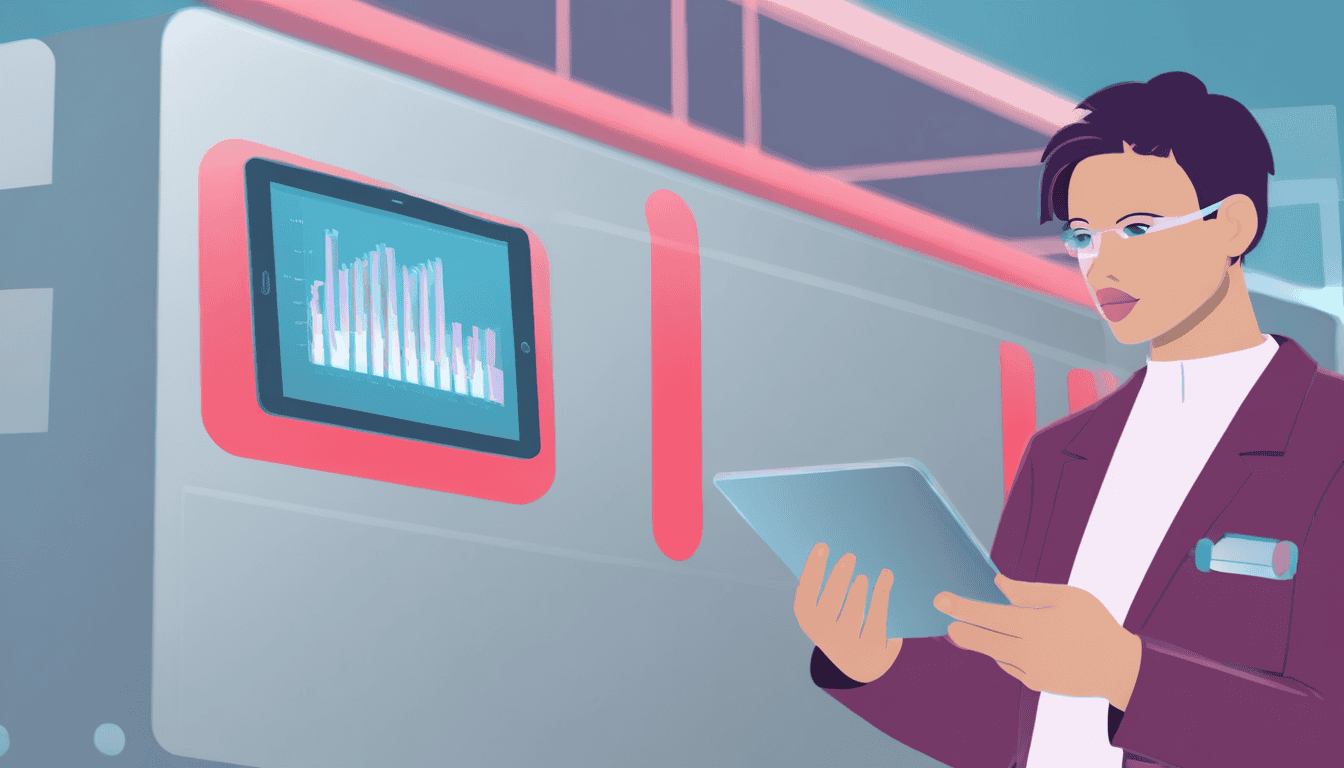

Continuous Improvement: Engage in continuous improvement practices, regularly evaluating and enhancing manufacturing processes to boost efficiency and product quality. Demonstrating a commitment to innovation reassures clients that they are partnering with a forward-thinking manufacturer.

Leveraging Technology: Invest in cutting-edge technologies and automation to improve production capabilities and product offerings. Staying ahead of technological advancements positions the manufacturer as an industry leader and provides clients with innovative solutions.

Elevate Quality and Efficiency

Ensure excellence with our Digital Transformation Starter Kit. Get templates and guides for rigorous quality control and continuous improvement.

Summary and Final Thoughts

Exceeding customer expectations in B2B manufacturing is not just about meeting basic requirements but about delivering exceptional value through customised solutions, proactive communication, and a steadfast commitment to quality and innovation.

By adopting these strategies, manufacturers can build strong, enduring relationships with their clients, leading to higher retention rates and increased revenue. In a market where client loyalty is paramount, focusing on customer satisfaction is a strategic imperative that can significantly enhance a manufacturer’s competitive edge and long-term success.

We Help Manufacturers

Make Great Quality Products

Let's talk! Book a 1:1 call with our

CTO to discuss your digital transformation.