However, there are dramatic changes happening in the industry. Cleaner, safer and more efficient and technologically advanced vehicles are being developed. The main objective of the UK automotive industry is that it must remain globally competitive.

The opportunity presented by Connected Manufacturing is to reduce manufacturing costs and respond more effectively to customer demand. This will, as a result, help UK automotive manufacturers remain globally competitive.

Globally, the automotive industry is prioritising digitalisation with initiatives underway in Germany, Japan and the USA. On average the UK’s vehicle plants are the most productive in Europe. For this reason, the UK will need to embrace Connected Manufacturing to maintain and improve on this.

Many UK vehicle manufacturers are only initiating pilot projects so far. A lot of SME suppliers are not embarking on any connected manufacturing projects. Manufacturers and suppliers are predicting substantial benefits from connected manufacturing including; shorter lead time, productivity gains and more customised vehicles. However, lack of knowledge and skills to implement connected manufacturing are causing key barriers to entry for many companies.

Technology is Accelerating Change in the Fourth Industrial Revolution

Manufacturing processes have been automated for many years, with data being used for analysis and process improvement. However, some key technologies are causing a rapid growth in the use of manufacturing data:

- Collecting, Storing and Transmitting Data – It is now possible to connect devices and sensors at low costs throughout a factory, using ethernet, Wi-Fi and RFID technology. Moreover, these sensors allow a huge amount of data about the manufacturing process to be stored.

- Analysing Data – Artificial Intelligence and predictive analytics can now be performed on large manufacturing data sets, thus giving insight into manufacturing processes.

- Interacting with Data – Intuitive interactions can now occur between the physical and digital world, with touchscreens, augmented reality and virtual reality.

- Producing Digital Organisation – The entire production system can be re-imagined with digital manufacturing technologies like 3D printing, robotics and Manufacturing Execution Systems (MES).

- Protecting Data – Security of data is becoming less of a concern, with improvements in cybersecurity and blockchains allowing companies to store vast amounts of data in the cloud.

Connected Manufacturing in the Automotive Factory

Once an automotive factory has implemented Connected Manufacturing, businesses will see immediate benefits in the following areas:

- Designing Production Lines Quickly – Virtual reality and analytics can be used to design and optimise the flow of materials and production assets.

- Improving Vehicle and Product Launches – Using sensors to collect and store product development and pre-production data, which can then be automatically shared with customers. This can cut product development and approval time in half. Read more about our product Metest for rapid R&D product development testing.

- Optimising Factory Throughput – Digital Twins of entire production lines can be used to simulate alternative production processes, to remove bottlenecks and respond to production demand. Manufacturing Execution Systems (MES), can be used to reschedule production plans based on logistics disruption of supplier failures.

- Improving Vehicle Quality – Connected sensors and product diagnostics can be used to immediately identify defects at the earliest stage in manufacture. This significantly reduces the cost of rework and helps identify the root cause of quality issues. Read more about our product Tascus for automotive MES.

- Improving Plant Maintenance – Machine sensors and predictive and preventative maintenance software are used to reduce machine downtime. Read more about our product Preventt for managing predictive and preventative maintenance.

- Reducing Inventories – Real-time estimates of supplies with track and trace inbound supplies.

Benefits to the UK Automotive Industry

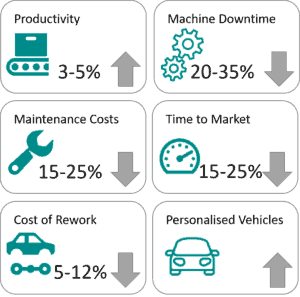

There are substantial benefits to be gained from the UK automotive industry adopting connected manufacturing, including the following:

Information Source: SMMT & KPMG Automotive Industry Survey 2017

Summary

The UK is ready to capitalise on Connected Manufacturing. We have the most productive automotive factories in Europe, with a diverse range of supplier manufacturing companies and IT specialists, that can work together to fully implement the business opportunities of Connected Manufacturing. We need to capitalise on this opportunity in the UK immediately, to remain competitive with the automotive industries in Germany, Japan and USA.