Device Communications

Once a secure network that enables a connection between production devices is in place, a system must be created for connecting devices that will allow production machines to communicate with each other.

There are two main reasons for enabling production devices to communicate:-

1. Monitor Machinery Status

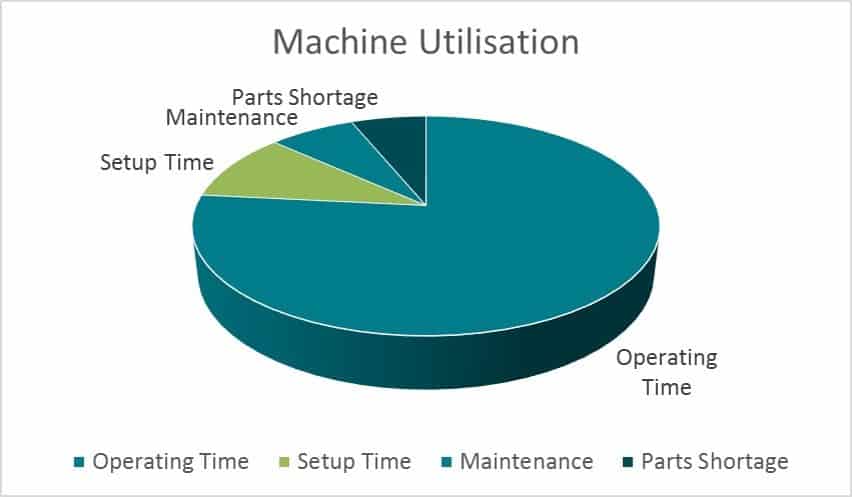

Firstly, acquiring and storing machinery status. Health and production data will enable you to perform machine data analysis to predict its performance. Doing this can also help you decide when and how the machine should be used and ultimately improve its production efficiency and machine utilization.

2. Control The Production Processes

Secondly, sending commands to the production equipment to control what production processes to perform. This reduces manual interaction and decision making within the production process, therefore making the production process more efficient and consistent.

By taking out the manual decision making of which program a machine should run and having a software application make that decision, allows several key benefits to arise:-

- The risk of making production mistakes is greatly reduced. The correct machine program and setting can be configured correctly from the products routing and Bill of Materials (BOM), instead of being selected manually from a work instruction.

- A greater variety of different products can be routed through the same production line, with extremely small batch sizes. A software application will select the new machine configurations for each new product. As a result, change-over times can be drastically reduced between different parts.

- The result of each production operation can be recorded. Consequently, product managers can instantly see the current production status of products moving along the production line. Product certifications can be automatically created and also submitted directly to customers.

Connecting Devices

There are several types of manufacturing processes to connect to, simplified it by categorising them into manual and automated processes. Manual processes are primarily controlled by a human operator, whereas automated processes are primarily controlled by an automation device eg. a PLC or robot.

Each process must acquire data from the production process. The data is then broadcast out using a standardized data format. This is a data formatting schema that can be used for every manual process, machine or device. It contains the structure that allows software applications to understand the type of device sending the production data, and also the production data characteristics contained.

There are many web-formatted data formats that can be used as a starting point for this communications protocol. JSON and XML being two popular data transfer standards.

Currently, there are no agreed standards for transferring machinery data using Industry 4.0, so this is an area of the technology that needs to be monitored. This will ensure that systems developed now, can adapt and conform to burgeoning standards for data communication within Industry 4.0. Using a popular format like XML or JSON and making customized schemas within that framework for your device communications is, therefore, a good starting point.

Connecting Manual Process

Any manual or semi-automated process means we need to add sensors and a User Interface (UI). This gives the manual operator instruction of the manual process to be performed and also feedback on the results of the manufacturing process. The process HMI and process sensors must receive production information and send production data out, that the networked production line can understand and process.

A National Instruments Wireless Data Acquisition (DAQ Device)

To implement a system like this requires either intelligent Industrial Internet of Things enabled sensors or regular sensors connected through a device, that can process incoming commands and broadcast the sensor data out using a standardised data format.

Connecting Automated Processes

If a process is automated, a device will be controlling the process – typically a PLC or Robot controller. To connect these types of devices together, an industrial protocol will be used. The right type of protocol often depends on which protocol can be supported by the PLC or robotic device that controls the process.

There are numerous established industrial protocols existing today, including:-

- Modbus

- OPC DA / OPC UA

- TCP/IP

- Profinet

- Open Protocol

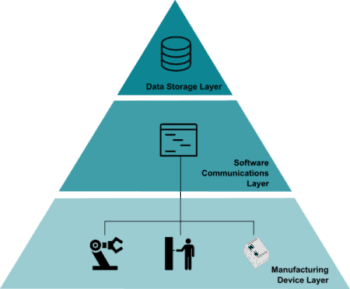

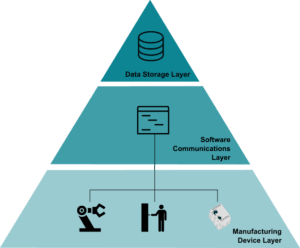

Each of these industrial protocols can communicate with computers, using an Ethernet network connection. A key requirement for the system is a software layer that sits between the devices that use the machine-specific protocol. This software layer can, in a generic format, broadcast the current machine status. It can also receive and send commands to the machine, using a protocol that it understands.

An Overview of an Industry 4.0 Production Software System, where manufacturing devices communicate through a Software Communications Layer.

As an example of this, we have developed our Industry 4.0 software product Tascus. It has a device communication software layer that can communicate with any industrial protocol. It also acts as a software layer to send and receive information to each manufacturing process. The Tascus software layer then stores its production data in a SQL Database for analysis and production tracking.

Read the next part of the guide: Part 3 – Connecting Entire Production Operations