Martin discusses the evolution of manufacturing processes and the dawn of the next stage – Mass Customisation, in an article published in Control Engineering Europe magazine.

Mass Customisation is the ability to create custom, almost bespoke products at the same volume and cost of mass produced products. It goes beyond the ability to change cosmetic features of a product, or to offer a number of product variations. It is the ability to offer a vast array of product configurations, and to cost effectively integrate this into a production system.

When Martin has been involved in developing Mass Customisation processes, the goal has been to remove manual decision making from the production process and to move the decision making into the production system. The outcome is that a wide variety of products can be integrated into a production line with minimal impact.

One of our clients, Bifold Fluid Power, had traditionally designed bespoke products as and when orders were presented. However, the company has now restructured most of its core products to be fully configurable. These use more structured part codes, and a set of rules are configured to determine which configurations are permitted.

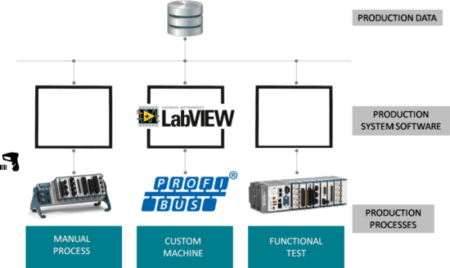

Tascus, our Smart Production software solution is a Manufacturing Execution System that will enable you to connect various production operations throughout production lines and throughout the factory.

UK +44 151 558 0810 | US +1 833 699 2469