Manufacturing Work Instructions: Best Practices for Quality

Clear and effective work instructions are crucial for ensuring quality and efficiency on the production floor.

Work instructions provide detailed guidelines for workers to follow, helping to reduce errors, enhance safety, and maintain consistency in product output.

As manufacturing processes become increasingly complex, leveraging advanced tools like digital manufacturing execution systems (MES) can significantly improve the creation and management of these instructions.

In this article, we will explore best practices for developing manufacturing work instructions that not only streamline operations but also enhance traceability and compliance.

Streamline Your

Production Floor

Download our free Digital Transformation Starter Kit to start crafting clear and effective work instructions that enhance quality and efficiency.

How to Create Effective

Manufacturing Work Instructions

Craft Precise

Work Instructions

Get our Starter Kit to learn best practices for developing concise, clear, and visually supported manufacturing work instructions.

How to Create Effective Manufacturing Work Instructions

Be Clear and Concise

Write instructions in simple, easy-to-understand language. Avoid jargon and technical terms that may confuse workers.

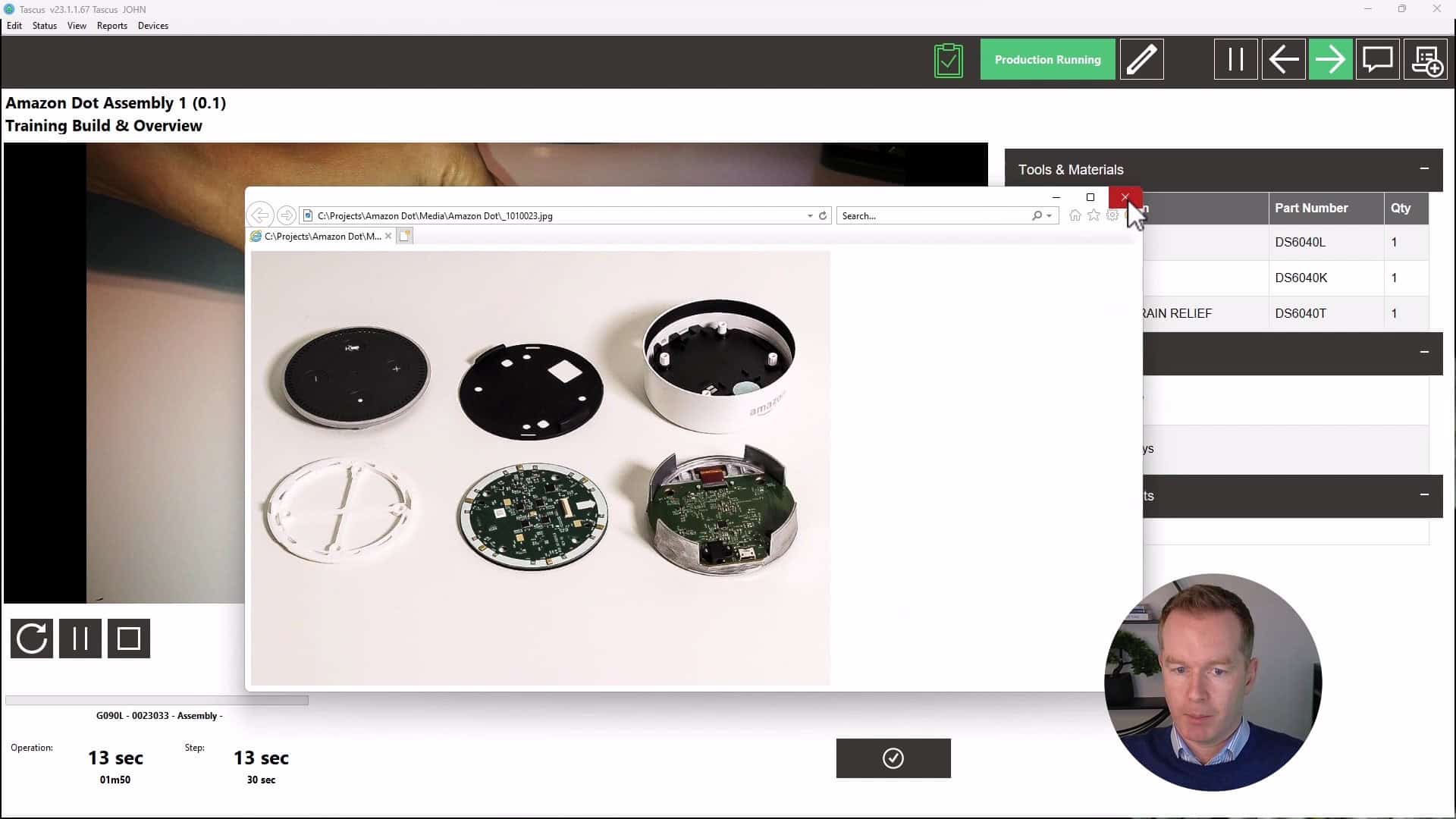

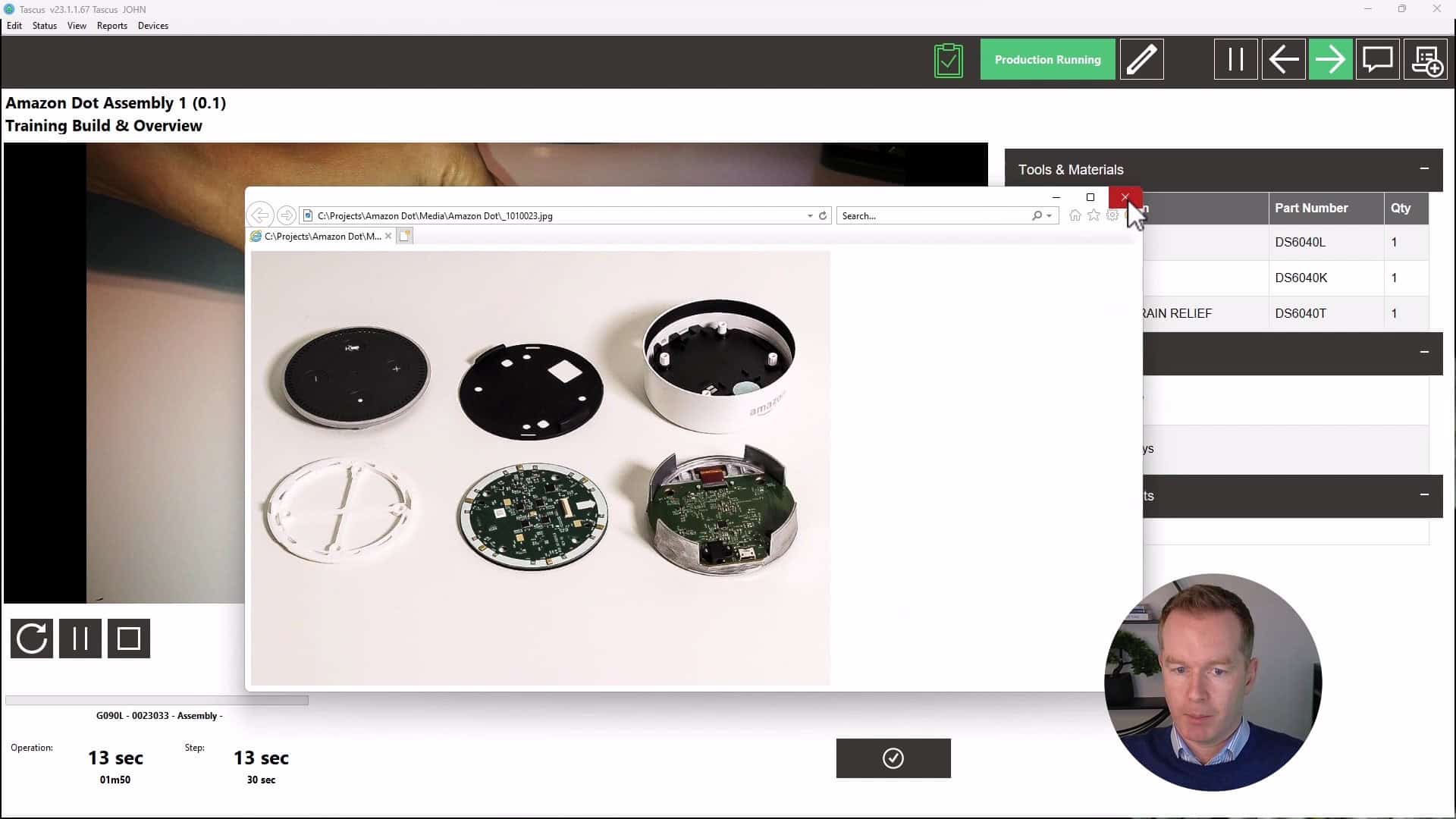

Incorporate images, diagrams, and videos to visually demonstrate steps and processes. Visual aids can often convey complex information more effectively than text alone.

Break down tasks into clear, sequential steps. Number each step and use bullet points to make the instructions easy to follow at a glance.

How to Create Effective Manufacturing Work Instructions

Leverage Digital Tools

for Efficiency and Accuracy

Implementing an MES like Tascus can streamline the creation and distribution of work instructions. Digital systems allow for easy updates, ensuring that workers always have access to the most current instructions.

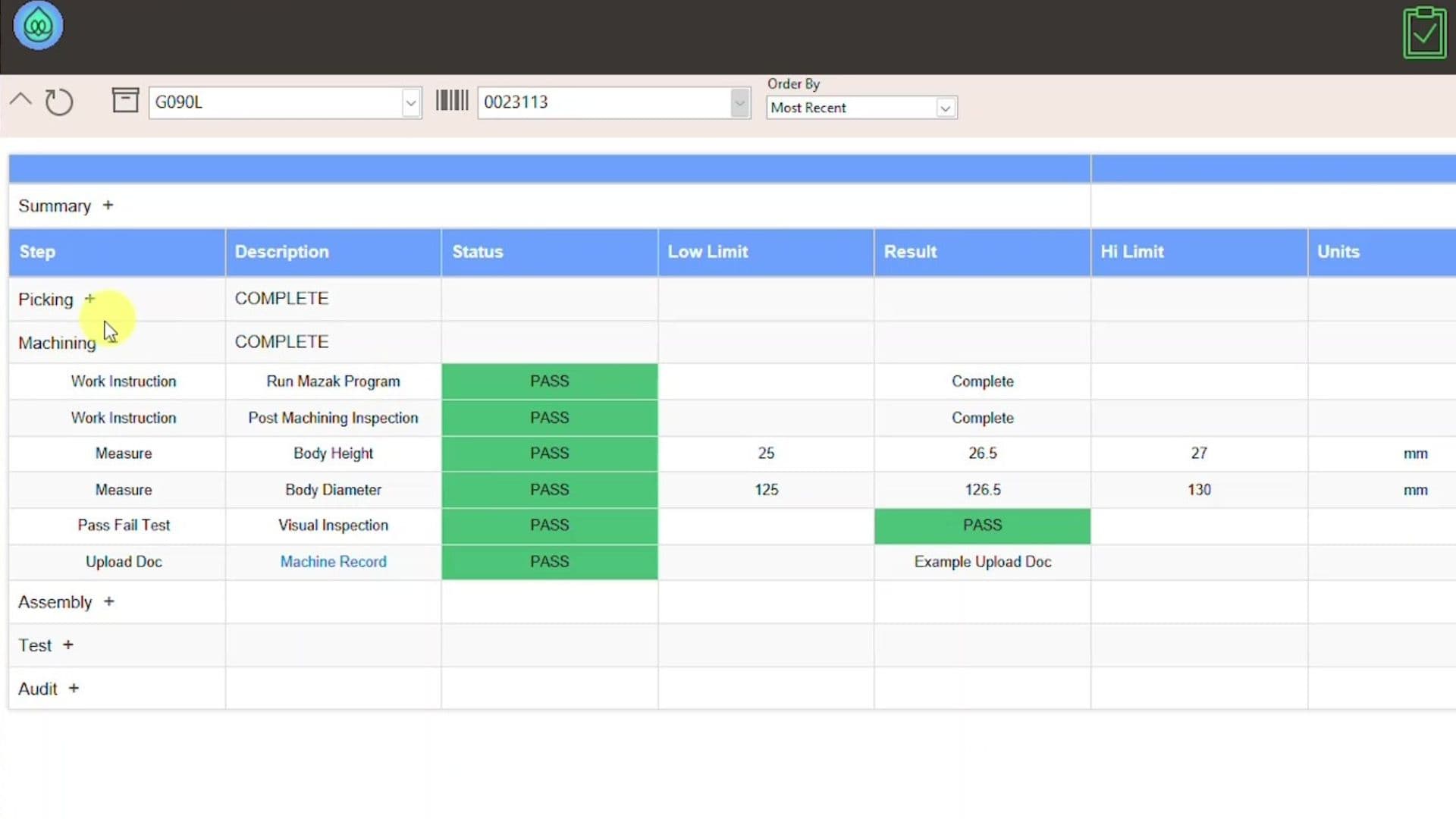

Digital work instructions can be linked to specific batches, products, or work orders. This enhances traceability, making it easier to track compliance and identify the root cause of issues if they arise.

Digital systems can provide real-time feedback and data collection, allowing for immediate adjustments and continuous improvement of work processes.

Optimise with Practical Tools

Utilise the Excel templates and instructional video in our Starter Kit to streamline the creation and management of work instructions, ensuring accuracy and ease of updates.

How to Create Effective Manufacturing Work Instructions

Incorporate Feedback

and Continuous Improvement

Encourage feedback from operators and technicians who use the work instructions daily. Their insights can help identify unclear instructions or potential areas for improvement.

Schedule regular reviews of work instructions to ensure they remain relevant and effective. Update instructions to reflect changes in processes, equipment, or materials.

Provide comprehensive training for workers on how to use the work instructions and any digital tools associated with them. Ensure that support is available for any questions or issues that arise.

Final Thoughts

Creating effective manufacturing work instructions is essential for maintaining high standards of quality and efficiency in production.

By focusing on clarity, leveraging digital tools like manufacturing execution systems, and incorporating continuous feedback, manufacturers can ensure that their work instructions are both practical and powerful.

Digital solutions not only enhance the ease of updating and distributing instructions but also improve traceability and compliance, providing a significant advantage in today’s competitive manufacturing landscape.

Implementing these best practices will help manufacturers optimise their operations, reduce errors, and maintain a safe and productive work environment.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?