“Industry 4.0 is not just about technologies. It is also about new ways of solving problems, creating unique experiences and accelerating business performance.” Bjorn Johansson – PwC

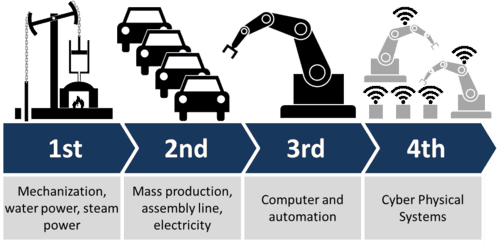

An overview of the 4 Industrial Revolutions (Christoph Roser at AllAboutLean.com.)

Benefits of Industry 4.0

Research by PwC suggests that companies who embrace Industry 4.0 will also have an advantage over their competitors. Their report talks about:

- 30% increases in productivity through increased machine uptime and usage.

- Reduced time to market for new products.

- Mass Customisation – Competitive advantage through meeting customer demand with ‘make to order’ products.

Companies who have implemented Industry 4.0 have reported an increase of 3% in ROI from cost savings (better use of labour and machinery), and also additional revenue (new digital products and data analytics services) of 3%.

Are you ready for Industry 4.0?

Once a company is convinced of the benefits of applying Industry 4.0 techniques within their company, they must assess the companies Digital Readiness Level (DRL) to understand what will be required to create a connected factory.

Our assessment of the key stages and requirements for implementing Industry 4.0 are:

- Big data from machines, manual processes and PLCs needs to be acquired and networked across the factory.

- Big data needs to be analysed and converted into smart business data.

- Machines should then be able to make the business decision currently being made by people.

“In the future, your IT infrastructure may be more valuable than your production assets”.

Consequently, the major benefit of implementing this will be reduced costs from better use of labour and machinery. There can also be additional revenue from new digital products and data analytics services.

What next?

We will take you through each of the stages required to set up and implement Industry 4.0 in your manufacturing organisation, step by step.

Read the next part of the guide: Part 1 – Creating a Secured Network Factory.