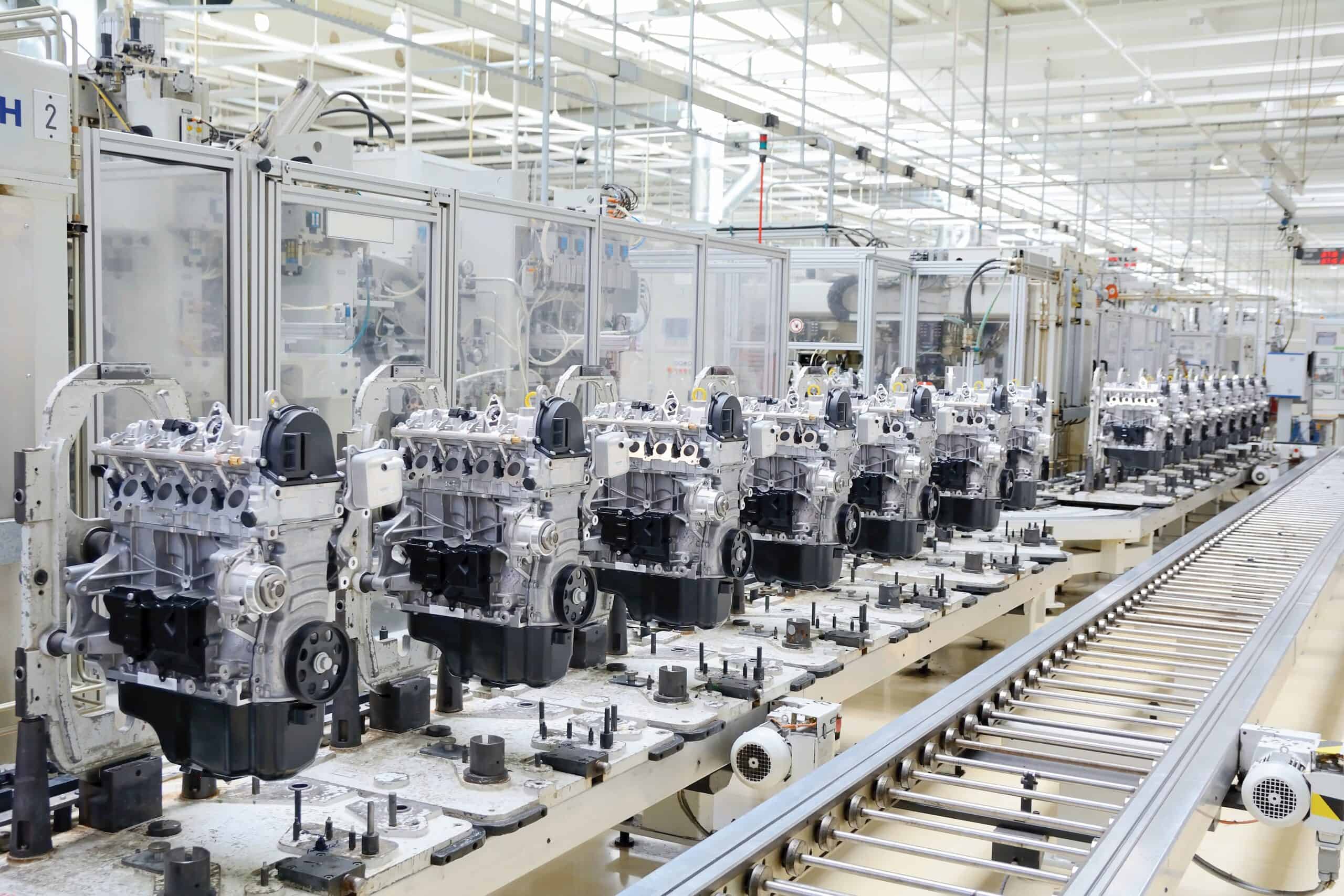

Transform Your Manufacturing Quality

With Award-Winning Digital Work Instructions

Our Manufacturing Execution System (MES) Tascus is user friendly and give you full visibility of your production operations. It helps you to ship excellent quality, discrete product on time, with full traceability.

Our Clients

Achieve Unrivalled Product Quality

Digital Work Instructions eliminate costly manual errors. Images, video and text are displayed on a touchscreen guiding each operator, step by step.

Barcode scanners ensure that correct parts are picked every-time.

Tascus links to vision systems and tool sensors for Process Integrity Checks. This means that your operator is only allowed to move on with the build, if the last part has been installed correctly.

Experience Rapid Build Times

The timer in Tascus increases productivity, as it allows you to find the operators that need more training from the ones that perform the best.

Often customers will use this feature to incentivise staff, to build faster and keep them loyal with performance related pay.

Employ Faster Training

Tascus guides operators with simple, visual and easily updated Digital Work Instructions.

We strive to ensure that even the least tech savvy person in your company will find it easy to use.

Automate Traceability for Accuracy

Automated traceability saves time and eliminates manual data entry mistakes.

Product is effortlessly tracked for compliance and rework, through each production stage.

Real Time Reports

Gain actionable insights with instant remote visibility into your production status, from anywhere. Generate in seconds, comprehensive visual data reports that empower you to:

- Present to your team

- Identify bottlenecks

- Track key metrics

- Seize opportunities to maximise efficiency

How Husco International Ensured Quality to Win New Business:

Tascus helped Husco International win a £5 million contract with Caterpillar and reduced rework by over £250,000 a year.

By discarding unreliable paper processes and investing in Tascus, Husco International were able to gain a sizable return on their investment.

Uncover the secrets behind their success.

Our Mission

“We strive to create flow in the working lives of manufacturers. In a positive work environment with reliable systems, teams can showcase their highest quality products with pride.”

We are a family-run business with a passionate team.

We prioritise developing software that is easy to use and delivers massive impact on multiple levels for our valued clients.

Martin Griffiths | CEng/CLA, Co-Founder

What our Customers are Saying:

"Exceeded Expectation..."

"Metis provided an excellent control system upgrade from limited RFQ. Integration of Control System software, DAQ and field wiring exceeded expectation with minimal debug required and in a timely manner. Martin’s industrial /manufacturing knowledge and experience proves to be an invaluable asset in bringing concept through to reality."

"Helps us Make our Products Easily"

“Tascus helps us to make our products easily and with full traceability. We are now capturing assembly times which is helping us to streamline our processes.”

"The Ability to Make Decisions Quickly"

“We needed an MES system to allow the key users remote access to the production data. The MES system allows for continuous monitoring of all production parameters and key performance indicators with the ability to make decisions quickly.”

Quality Manager

Elevate Your Potential

At Metis Automation, we empower manufacturers to achieve their full potential when it comes to building high quality products. Our MES Tascus also improves productivity and simplifies compliance.

Choose us for unparalleled expertise and a transformative solution.

Ignite Your Digital Transformation!

Let’s talk! Book a 1:1 Digital Strategy Session with our Chief Technical Officer to

discover what your journey towards digital transformation could look like.