How to Implement Traceability in Manufacturing

Traceability in manufacturing has become essential. It drives quality, compliance, and operational efficiency. With the right systems in place, manufacturers can track every product from raw material to finished goods, ensuring data accuracy, faster problem-solving, and customer confidence.

Here’s how to put traceability into action across your factory floor.

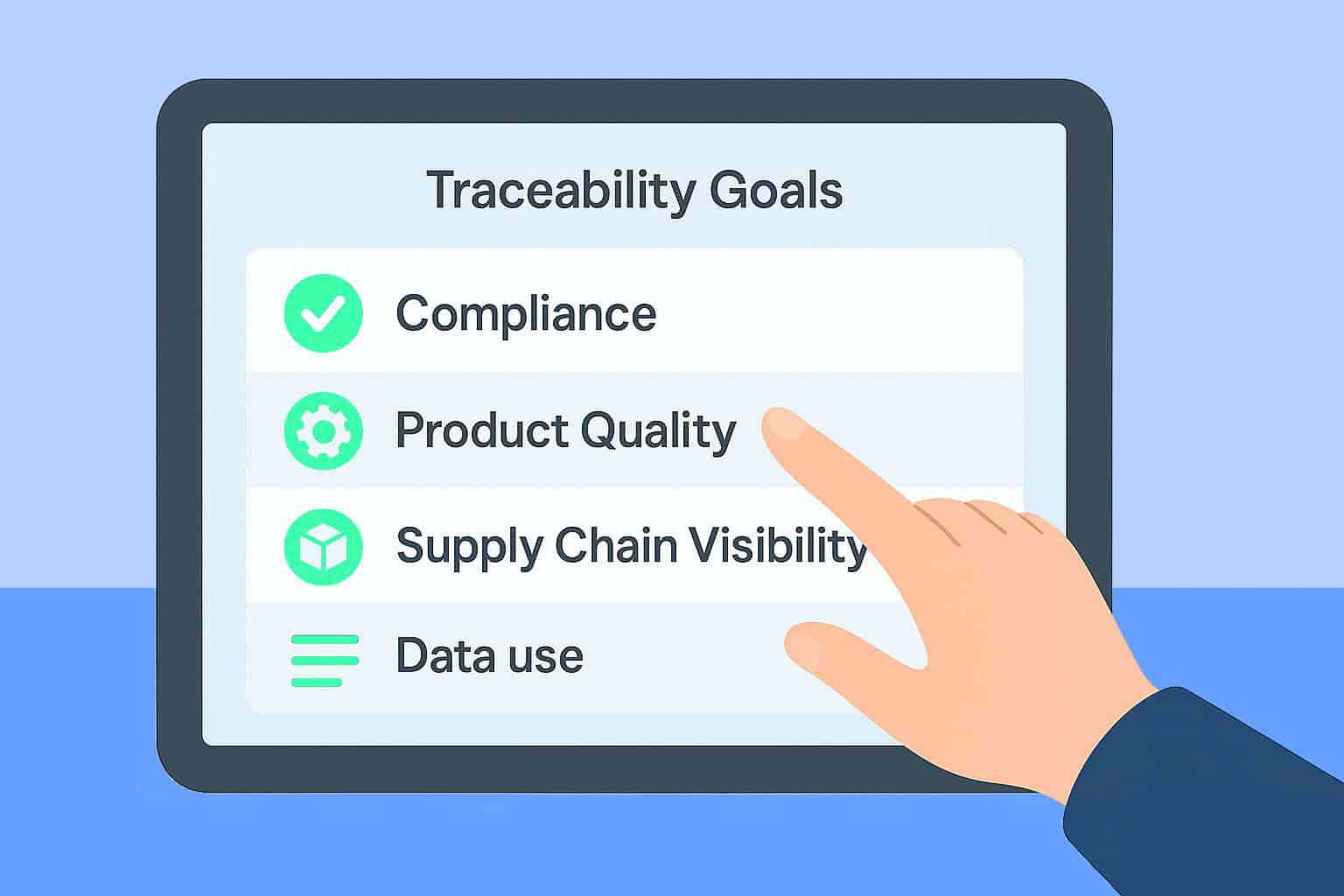

1. Set Clear Goals for Traceability in Manufacturing

Start by defining what you want traceability to achieve. This could be meeting regulatory requirements, improving product quality, or increasing supply chain visibility. Be specific about what data needs to be captured, batch numbers, operator actions, test results, and where it will be used.

For an in-depth understanding of how traceability enhances supply chain sustainability and resilience, refer to the World Economic Forum’s report on Digital Traceability: A Framework for More Sustainable and Resilient Value Chains.

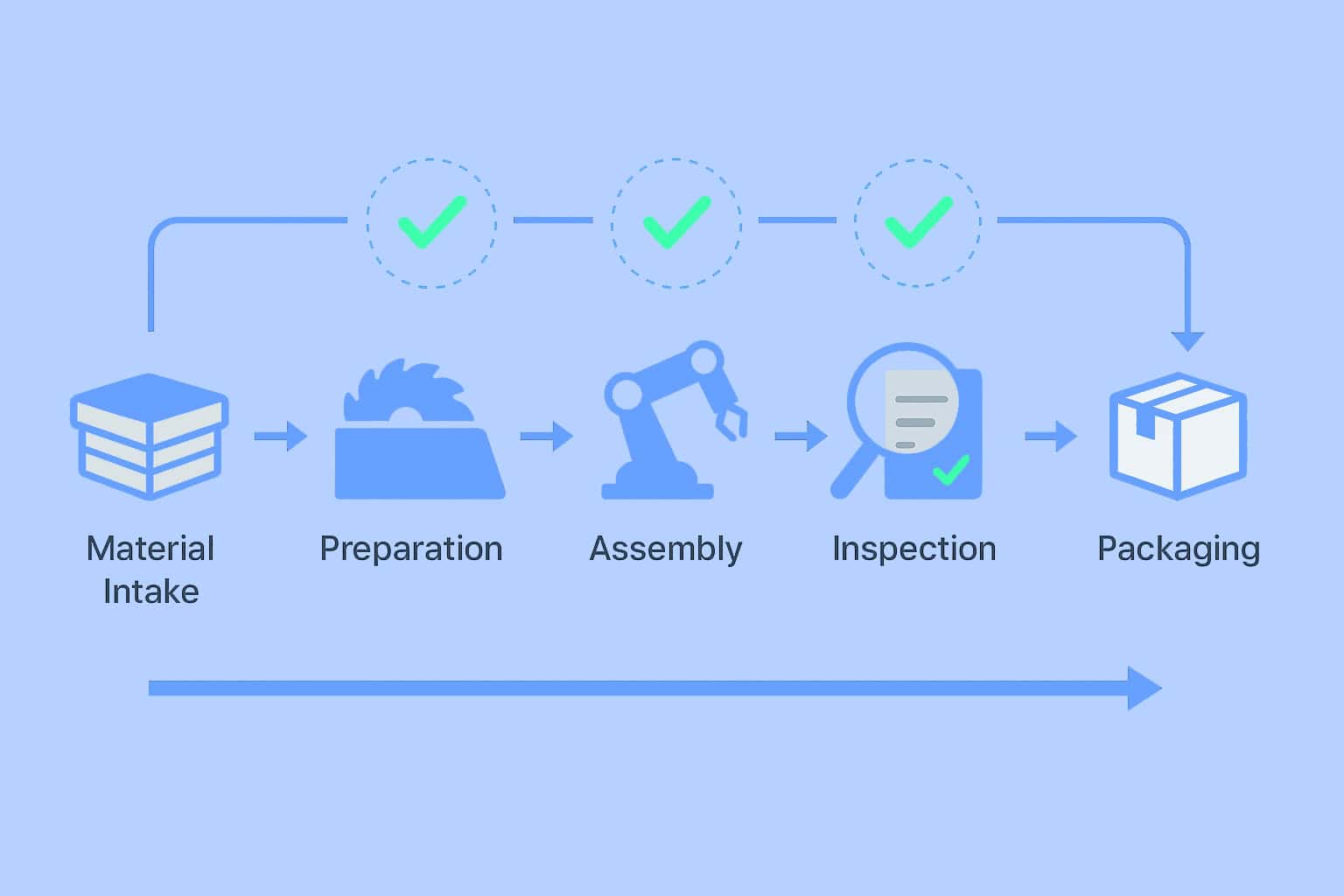

2. Map the End-to-End Production Process

Create a step-by-step map of your production line, from material intake to final dispatch. Identify the points where information must be recorded. This highlights where traceability controls need to be introduced or improved.

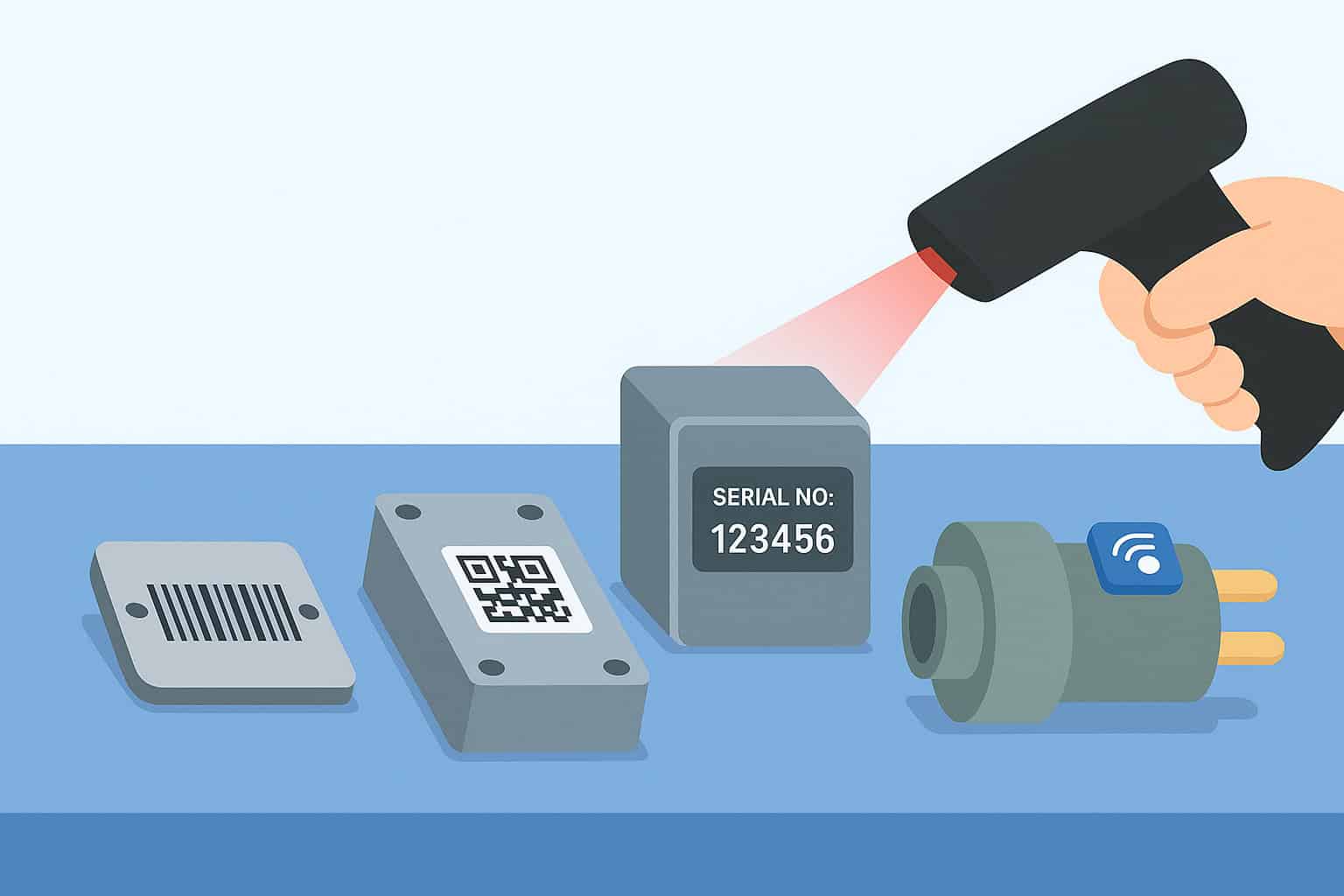

3. Use Consistent Product Identification

Assign unique identifiers to parts, components, and finished goods. Barcodes, QR codes, serial numbers, and RFID tags are common options. Consistency is critical, each item must be tracked the same way through every stage of production and delivery.

Tascus supports barcode scanning and RFID integration to simplify this process and reduce manual errors.

GS1 UK highlights the role of global standards in improving transparency and traceability in their article on why traceability matters.

4. Use a Digital MES to Automate Traceability

A digital Manufacturing Execution System (MES) like Tascus makes traceability faster, more accurate, and easier to manage.

Key traceability features include:

- Real-time data capture from every production stage

- Automated records of operator actions and inspection results

- Digital manufacturing travellers that meet compliance needs

- Live product tracking across the factory floor

With Tascus, you get a complete digital history of every product, without relying on paper.

The UK Government’s Advanced Manufacturing Plan outlines how digital tools like MES support innovation and productivity across modern manufacturing.

5. Train Your Team on Traceability Processes

Traceability only works when your team knows how to use it. Train operators to follow procedures, record data correctly, and work within the system. Tascus also supports operator skills validation, so only qualified staff perform specific tasks.

Final Thoughts

A clear traceability process improves product quality, ensures compliance, and protects your reputation. With defined goals, consistent tracking, and a digital MES like Tascus, manufacturers gain full control and confidence in their operations.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?