The Best Error-Proofing Tools for Reducing Production Mistakes

Every manufacturer wants to reduce production mistakes. The best way to do that? Use tools that make errors hard, or impossible, to happen in the first place.

Here’s a breakdown of the most effective error-proofing tools being used on the factory floor today, from physical jigs to smart tech.

1. Poka Yoke Fixtures

Poka Yoke means “mistake-proofing.” These are physical changes to the product or tooling that stop someone from doing the wrong thing.

Examples:

- A part that only fits one way

- A fixture that locks in place unless the correct component is used

- Different connectors to prevent cross-wiring

Why it works:

It takes the decision away from the operator. The wrong part simply won’t fit.

2. Pick-to-Light Systems

This system lights up the correct bin or location to pick the next part from. The operator follows the light, reducing the chance of grabbing the wrong component.

Why it works:

There’s no guesswork. It’s fast, clear, and easy to follow.

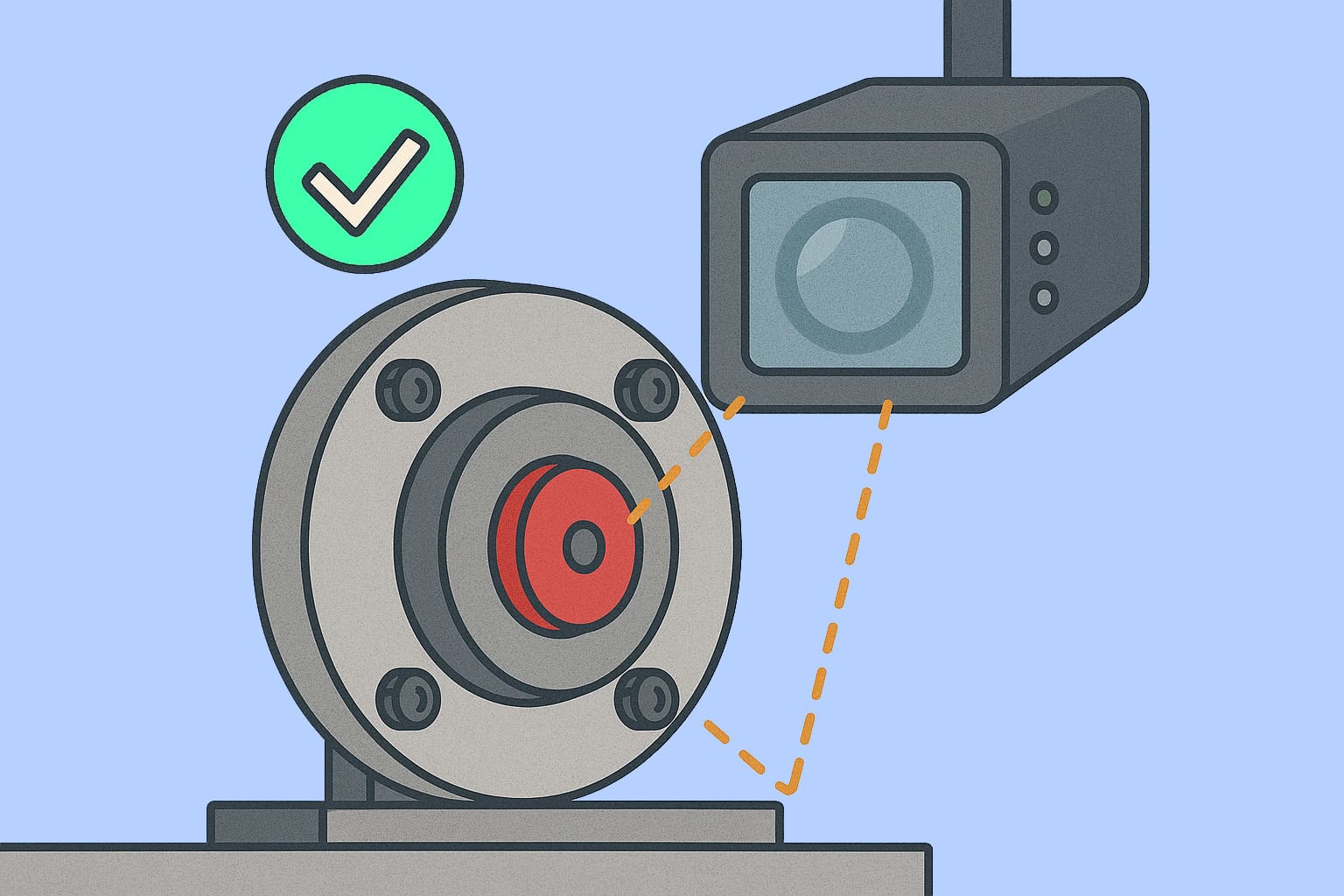

3. Smart Cameras and Vision Systems

Smart cameras check whether a component is in place, facing the right way, or has been fitted correctly. Some systems also detect missing screws or incorrect labels.

Why it works:

You catch mistakes instantly, before they move to the next stage.

For instance, SensoPart’s VISOR® vision sensors combine powerful software with compact hardware, offering configurable smart cameras that address a wide array of application challenges in industrial automation.

4. Digital Work Instructions

Digital Tools like Tascus, give operators step-by-step instructions with photos, alerts, and prompts – right at the workstation.

Features to look for:

- Images showing the correct part and orientation

- Instructions that update in real time

- Warnings if the wrong part is selected

Why it works:

Operators don’t rely on memory. It’s all in front of them, every time.

5. Barcode & RFID Scanning

Scanners verify that the correct part or tool is being used before a process starts.

Examples:

- Scan a component to confirm it matches the build spec

- Scan a tool to track torque settings

Why it works:

It stops the wrong part or tool from being used – automatically.

6. In-Process Quality Checks

Built-in checks after key steps ensure errors are caught early, not at the final test.

Examples:

- Functional tests

- Visual inspections

- Measurement checks recorded in real time

Why it works:

Fixing a mistake early is faster, cheaper, and easier than rework at the end.

For a deeper look at human performance strategies that reduce errors, this IAEA guide explains how early detection and feedback loops improve quality across high-reliability industries.

7. Colour Coding & Visual Controls

Simple but effective. Use colours, shapes, or labels to separate parts, tools, or areas.

Examples:

- Red bin vs green bin

- Colour-coded connectors or fasteners

- Labels that change colour when torqued correctly

Why it works:

It’s low-cost and instantly visible.

Final Thoughts

You don’t need to overhaul your factory to reduce mistakes. Just focus on the tools that remove the chance for error.

Whether it’s a smart camera, a digital instruction, or a simple fixture, you can stop problems before they start.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?