How to Solve Production Issue Reporting in Manufacturing

Every factory has issues. The real difference is how quickly you catch them, how easily you trace them, and how confidently you fix them.

Without a clear process for production issue reporting, problems get lost in paperwork, operators stay silent, and quality slips through the cracks.

In this post, we’ll break down what effective production issue reporting looks like in modern manufacturing, and how to build a system that helps you fix problems fast and stop them from happening again.

In this Article:

What Is Production Issue Reporting?

Production issue reporting is the process operators, supervisors, or engineers use to flag and document problems during manufacturing.

This could include:

✔ Defects spotted during assembly

✔ Equipment faults or breakdowns

✔ Process deviations

✔ Safety concerns

Effective reporting systems don’t just record issues, they enable fast response, root cause analysis, and long-term fixes.

Why Production Issue Reporting Matters

In today’s high-mix, high-speed manufacturing environments, even small issues can have big knock-on effects. Consequently, delayed reporting leads to:

✘ Increased rework and scrap

✘ Missed delivery targets

✘ Safety risks

✘Operator frustration

And without traceability, you’re left guessing when customers complain or audits roll around.

The right reporting process makes issues visible in real time, so you can act early, learn fast, and drive continuous improvement.

5 Essentials for Better Production Issue Reporting

Effective production issue reporting isn’t just about capturing data.

It’s about creating a process that’s fast, clear, and actionable.

The following five elements are the foundation for identifying issues early, responding quickly, and preventing repeat problems on your production line.

1. Make It Easy to Report

If reporting takes too long, it won’t get done.

Operators need fast, simple tools to raise issues from the line.

Look for systems that allow:

- One-click reporting from tablets or terminals

- Pre-set categories and checklists

- Space for notes and images

2. Capture Key Details

You need context to fix problems properly. A good report should include:

- What the issue is

- When and where it occurred

- Who reported it

- Impact on production

3. Notify the Right People Instantly

Waiting for someone to check a clipboard doesn’t cut it anymore.

Automated notifications ensure supervisors or quality engineers know about issues immediately, so they can step in fast.

With Tascus, alerts go straight to the right person’s screen, avoiding downtime.

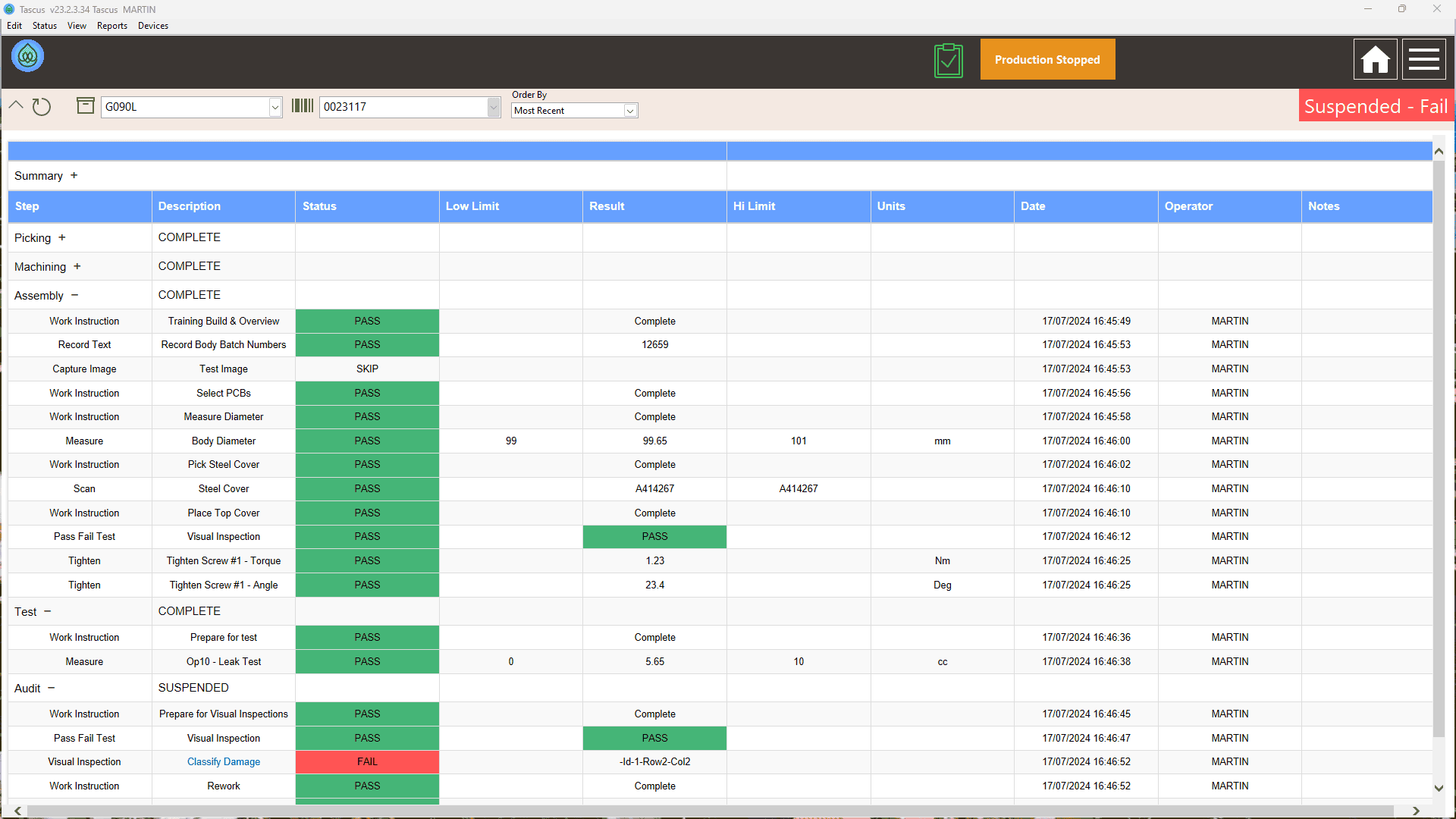

4. Track and Trace Over Time

Production issue data is gold for continuous improvement.

Your system should allow you to:

- Spot recurring problems

- Review response times

- Link reports to specific products, shifts, or machines

Tracking production issues over time isn’t just about visibility, it’s about building smarter systems. This article from LNS Research explains how integrating quality into daily operations drives faster responses and long-term gains.

5. Close the Loop

Reporting is just the start. Make sure you have a process to:

- Investigate root causes

- Document fixes

- Communicate outcomes back to the team

This builds trust and encourages more proactive reporting.

This final step is often where things fall short — but it’s where the real improvement happens. LNS Research calls this closed-loop quality: using feedback from reported issues to prevent the next one.

How Tascus Improves Production Issue Reporting

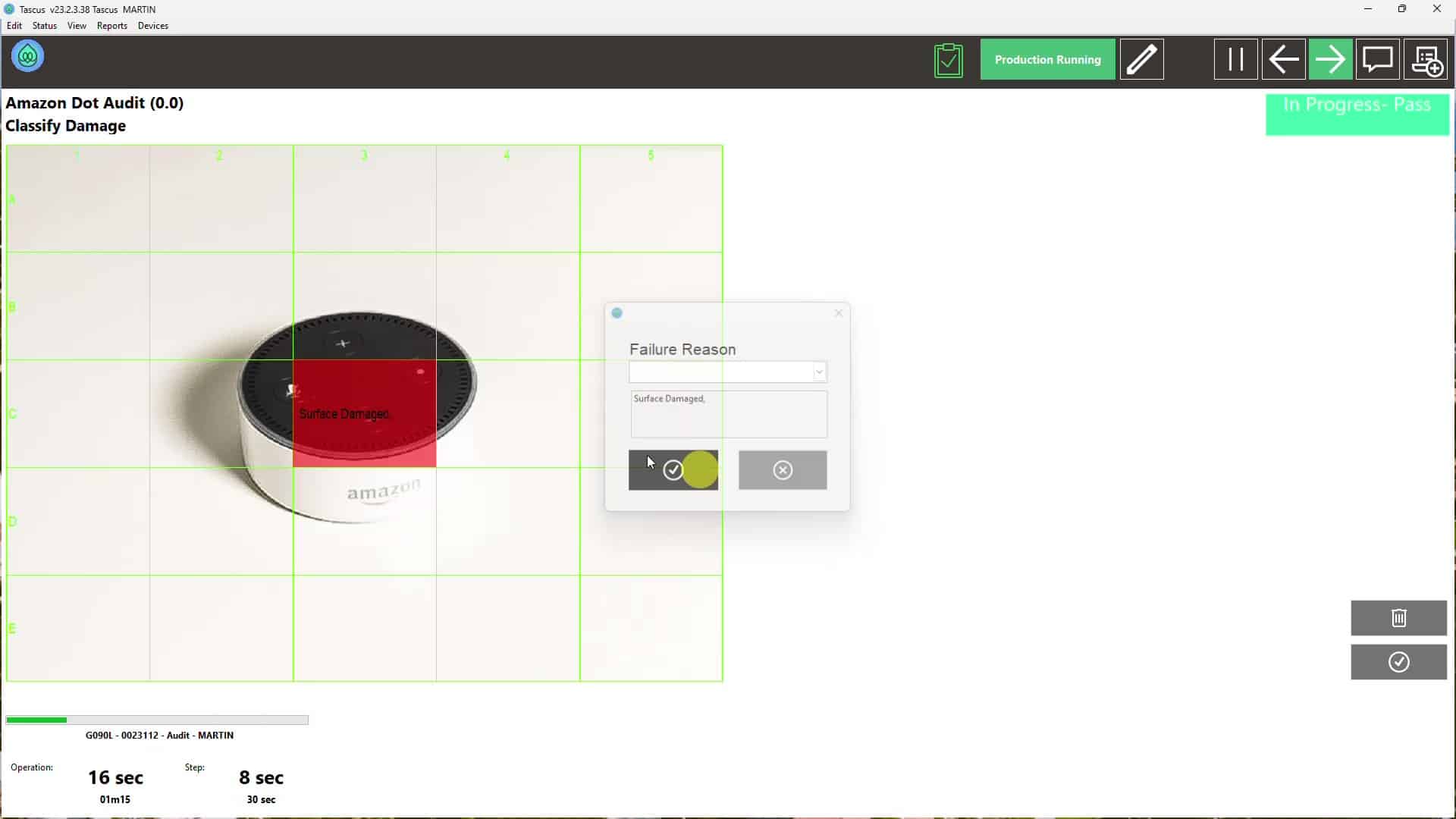

Tascus gives your operators the tools to report production issues in seconds, right from the workstation.

With instant notifications, live dashboards, and full traceability, you can catch problems early, respond faster, and prevent repeat issues.

Final Thought

Production issue reporting isn’t just a compliance box to tick. Instead, it’s one of the fastest ways to protect quality, improve flow, and empower your team to take ownership on the shop floor.

Get it right, and it becomes a driver for performance… not a burden.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?