How Operator Accountability Improves Production

Operator accountability means each person on the shop floor takes ownership of their part in the production process.

It’s not about blame, it’s about clarity, consistency, and traceability.

When operators know exactly what’s expected, and their actions are tracked, you get fewer mistakes, smoother shifts, and better results.

This Milliken article explores how manufacturers can create accountability through training, clarity, and measurement.

In this Article:

Why Operator Accountability Matters

Production speed is increasing. Teams are smaller. Quality standards are higher.

You need every operator to follow the process, and be able to prove it.

Operator accountability helps you:

- Reduce rework and missed steps

- Build a strong quality culture

- Prepare for audits with confidence

- Spot issues quickly and fix them faster

Operator Accountability in Action

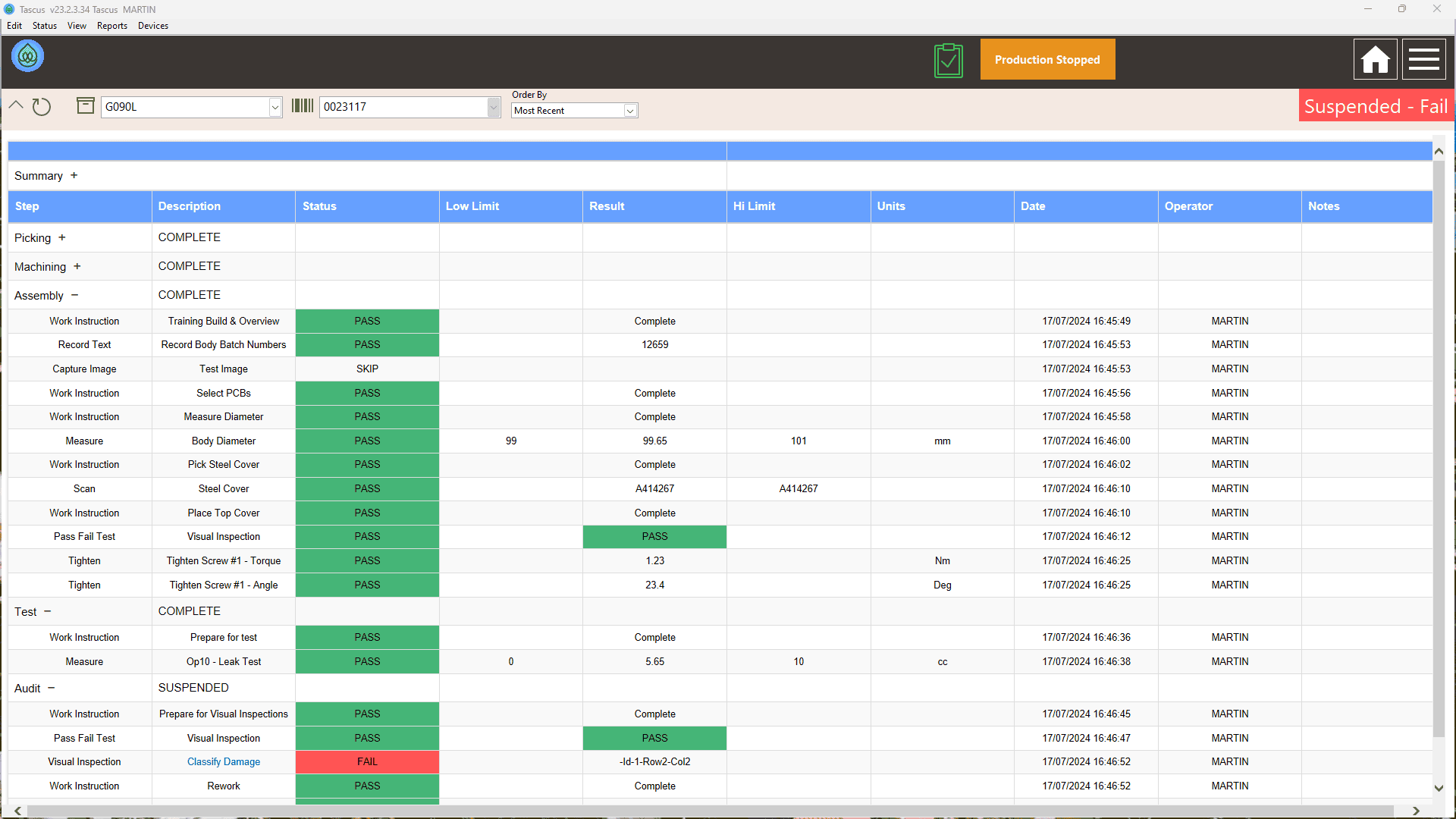

Digital Sign-Offs

Operators confirm each task is complete, step by step.

✔ Clear Instructions

There’s no guesswork. Everyone sees the same process, in the same format.

✔ Traceability

You know who did what, when, without chasing paper or memory.

✔ Fast Issue Reporting

If something goes wrong, operators can flag it on the spot. No delay, no confusion.

The Payoff

When accountability is part of your process, operators feel more confident.

They take pride in doing it right, and you gain visibility into what’s happening in real time, not just after something goes wrong.

Take Ocean Spray, for example, this case study shows how a cultural shift in accountability turned around a struggling plant’s performance.

Make It Easy to Get Right

Accountability works best when it’s built into the process.

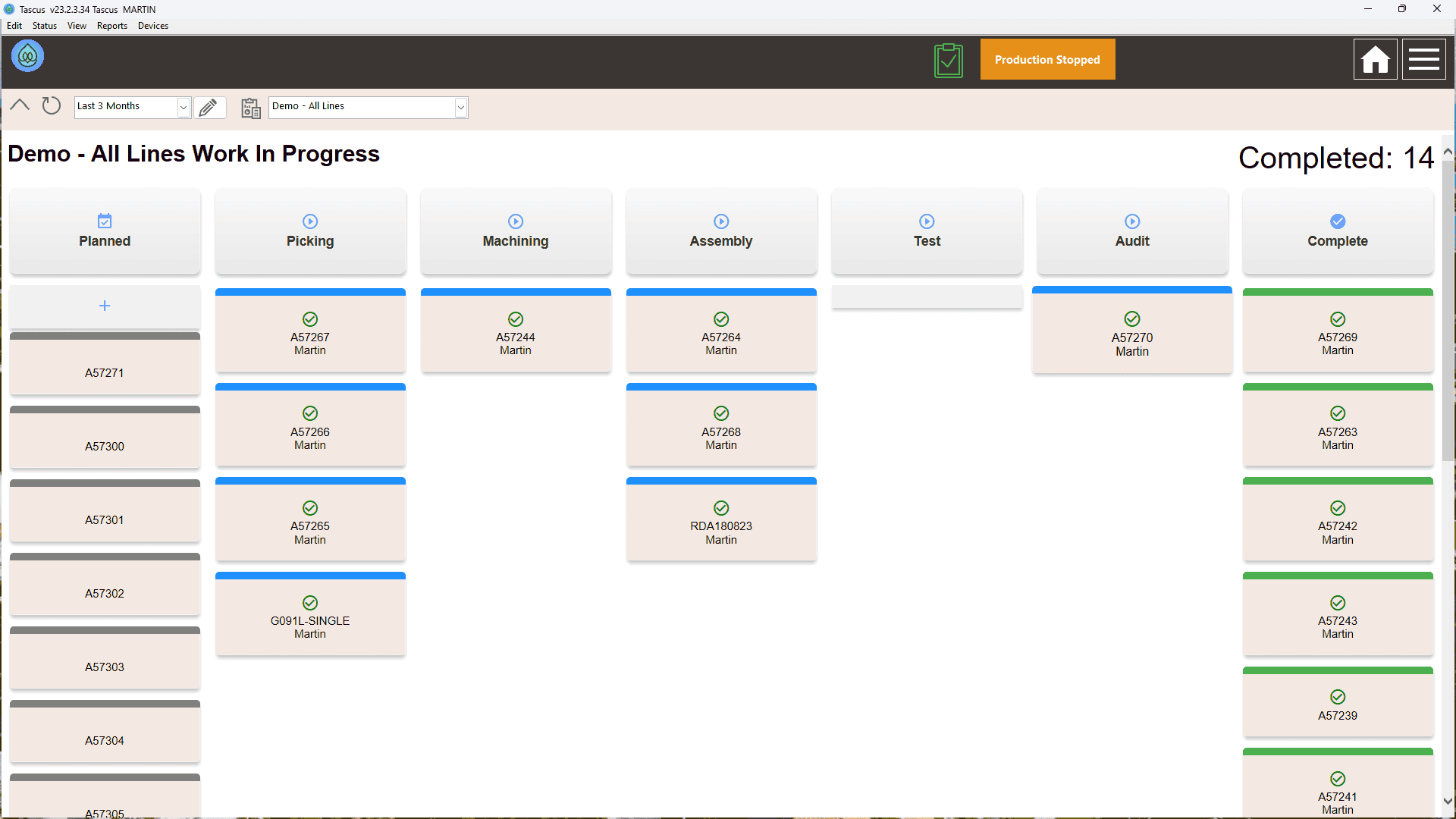

The easier it is for operators to confirm tasks and flag issues, the more likely they are to stay consistent and compliant. That’s where digital tools come in. By capturing sign-offs and tracking actions in real time, you remove the need for extra paperwork or separate systems.

Tascus supports this by making accountability part of the operator’s workflow, not an extra step. It helps teams stay on track without slowing them down.

As Industry Week confirms, accountability isn’t a one-off initiative, it’s a system that needs to be embedded into your operations.

Take the First Step

Want to build more accountability into your process without slowing things down?

Start with our Consistency Checklist, and see where your biggest wins could be.

Let’s Talk Tascus

Want to see how Tascus can cut errors,

speed up production, and simplify

compliance in your factory?