Tighten Multiple Fasteners in One Quick and Easy Step

Tighten Multiple Fasteners in One Quick and Easy Step

With the aim of making it simpler to control the process of tightening multiple fasteners in one process, we’ve just published a Tascus update that enables you to tighten a batch of fasteners in one Tascus step.

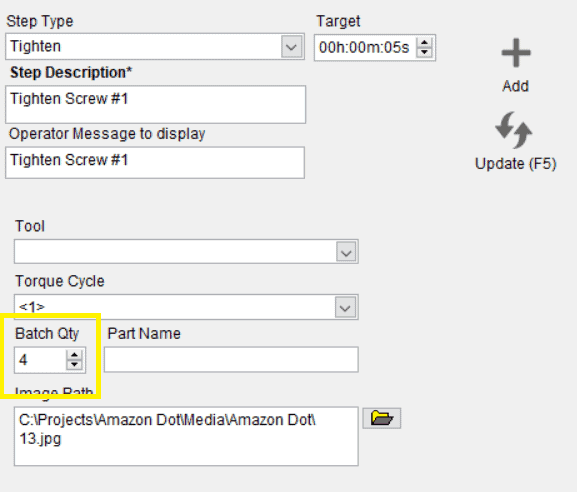

Configuring a Batch Tighten

To tighten a batch of fasteners, when configuring the step within the sequence, set the Batch Qty to the number of fasteners to be tightened.

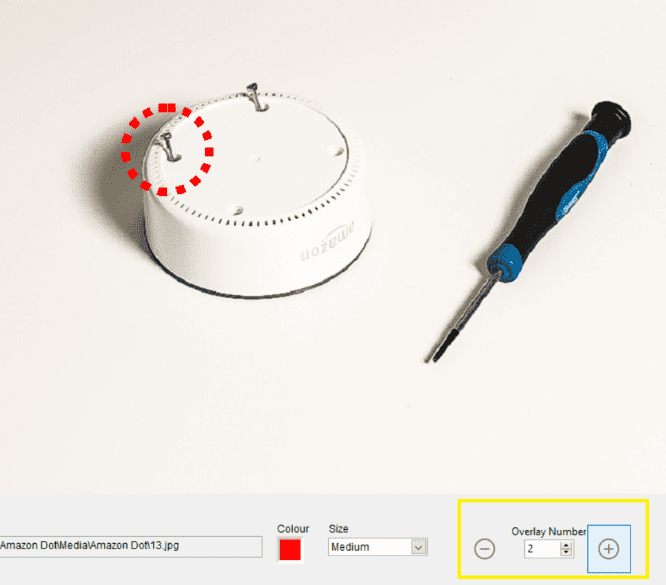

Update Image Overlays

To display image overlays highlighting which fastener to tighten, click on the Edit button.

Set the position of an overlay by clicking on the image , you can change the overlay number by using the + and – buttons on the bottom menu bar.

Want to learn more?

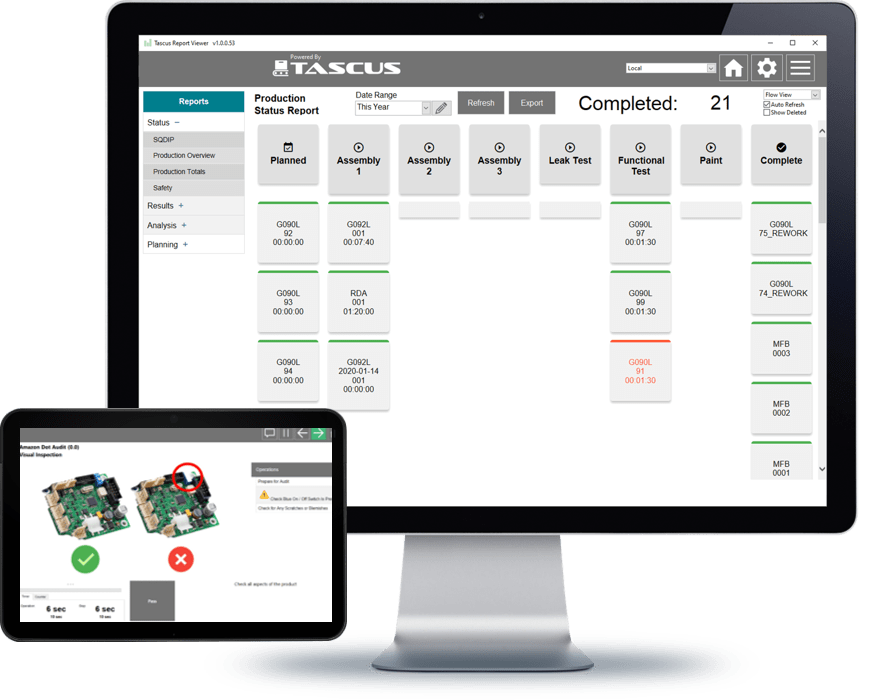

If you haven’t yet moved your manufacturing process to digital. You can watch a free demo of Tascus here.

Unleash the Power of Digital Manufacturing

Download our free Digital Transformation Starter Kit to set the gold standard for operational clarity and excellence.